Are you looking for a way to make a hole in your resin? We’ve covered you whether you’re looking to add a hanging loop or just need to get some air through it. Drilling a hole in the resin can be challenging, but there are a few ways to do it without a drill.

This blog post will show you some easy methods how to make a hole in resin without a drill and for making a hole in resin using items you probably have around the house. So if you’re looking for an easy way to make a hole in your next project, keep reading!

Summary: If you need to make a hole in resin without a drill, there are a few methods you can try. One is to use a soldering iron and heat the resin until it softens. You can then use a knife to make the hole. Another option is to use a hot needle to pierce the resin and then use a wire to make the hole.

12 Methods on How to Make a Hole in Resin Without a Drill

You can make a hole in resin without using a drill in several ways. We’ve compiled a list of methods you can use to get the job done, so keep reading to find out more!

Method 1: Use a Sharp Object

You can use a sharp object like a needle or a paperclip to make a hole in resin. Simply insert the sharp object into the resin and twist it to make a small hole. This is very easy to do and doesn’t require any special tools. However, be aware that this method might leave your resin with a small hole.

Method 2: Use a Heat Source

You can also use a heat source such as a lighter or a hair dryer to make a hole in resin. Hold the heat source close to the resin for a few seconds until the resin starts to soften. Then, use a sharp object to make a hole in the softened resin. After that, allow the resin to cool and harden before using it.

Method 3: Use a Chemical Solvent

If you want to make a large hole in resin, you can use a chemical solvent such as acetone or nail polish remover. Simply apply the solvent to the area where you want to make the hole and wait for it to dissolve the resin. Once the solvent has dissolved the resin, you can use a sharp object to make a hole. However, beware that this method might damage your resin.

Method 4: Use an Electrical Tool

You can also use an electrical tool such as a drill or a rotary tool to make resin holes. First, create a pilot hole in the resin with a tiny drill bit. Then, enlarge the hole with a more significant bit. Finally, smooth out the edges of the hole with a rotary tool. Make sure to wear protective gear when using this method.

Method 5: Use a Dremel Tool

Another way to make a hole in resin is to use a Dremel tool. First, put on some safety goggles and gloves. Then, attach a cutting bit to the Dremel tool. Next, hold the Dremel tool against the resin and start cutting. Beware that this method will create a lot of dust, so it’s also important to wear a mask.

Method 6: Use a Router

If you have access to a router, you can use it to make a hole in resin. First, create a pilot hole in the resin with a trim router. Then, enlarge the hole with a more significant bit. Finally, smooth out the edges of the hole with a rotary tool. This method will create a lot of dust, so wearing a mask is important.

Method 7: Use an Ice Cube

If you want to make a bigger hole in resin, you can use an ice cube. First, place the ice cube on top of the resin. Then, use a sharp object to make a hole in the center of the ice cube. The ice will prevent the resin from melting too much and make it easier to make a bigger hole. Remember to remove the ice before it melts completely.

Method 8: Use a Soldering Iron

Another way to make a hole in resin is to use a soldering iron. First, apply a small amount of solder to the area where you want to make the hole. Then, use the soldering iron to melt the solder and make a hole in the resin.

Method 9: Use an Ultrasonic Cleaner

If you have access to an ultrasonic cleaner, you can use it to make a hole in resin. First, fill the ultrasonic cleaner with water and add a few drops of dish soap. Then, place the resin in the cleaner and turn it on. The ultrasonic waves will create a hole in the resin. This is not for everyone, as ultrasonic cleaners can be expensive.

Method 10: Use Soap

You can use soap if you want to make a small resin hole. First, wet the tip of a sharp object with water. Then, dip the wet object in soap and insert it into the resin. The soap will lubricate the thing and make it easier to make a small hole. After that, allow the resin to harden before using it.

Method 11: Use a Hot Glue Gun

If you have a hot glue gun, you can use it to make a hole in resin. First, heat the glue gun. Then, apply the hot glue to the area where you want to make the hole. The heat from the glue will melt the resin, and you can then push the melted resin out of the way to create a hole.

Method 12: Use an X-Acto Knife

If you have an X-Acto knife, you can use it to make a hole in resin. First, insert the blade of the X-Acto knife into the resin. Then, twist the knife around to make a hole. Next, remove the blade from the hole. Finally, use a toothpick to widen the hole, if necessary. This method requires a lot of patience, but it’s worth it if you need a small hole.

Choose the method best suits your needs, and wear protective gear when necessary.

Precautions You Need to Know Before Making a Hole in Resin Without a Drill

- Always use personal protective equipment (PPE) when working with resin. This includes gloves, eye protection, and a respirator.

- Make sure the area you’re working in is well-ventilated.

- Avoid using power tools to make holes in resin. The heat generated can cause the resin to catch fire.

- If you must use a power tool, ensure it is equipped with a dust collection system.

- Never heat resin directly. This can cause the release of harmful chemicals and fumes.

- Use a piece of scrap wood to test your drill bit before drilling into the resin piece.

- Drill slowly and steadily to avoid cracking the resin.

- If you need to make a large hole, start with a little drill bit and work your way up.

- Use a countersink bit to avoid sharp edges on the inside of the hole.

If you’re unsure how to make a hole in resin, ask a professional for help.

Can Epoxy Resin Be Drilled?

Epoxy resin can be drilled, but it is important to use the correct drill bit and to go slowly. It is also a good idea to use a piece of scrap wood underneath the project to avoid damaging the work surface.

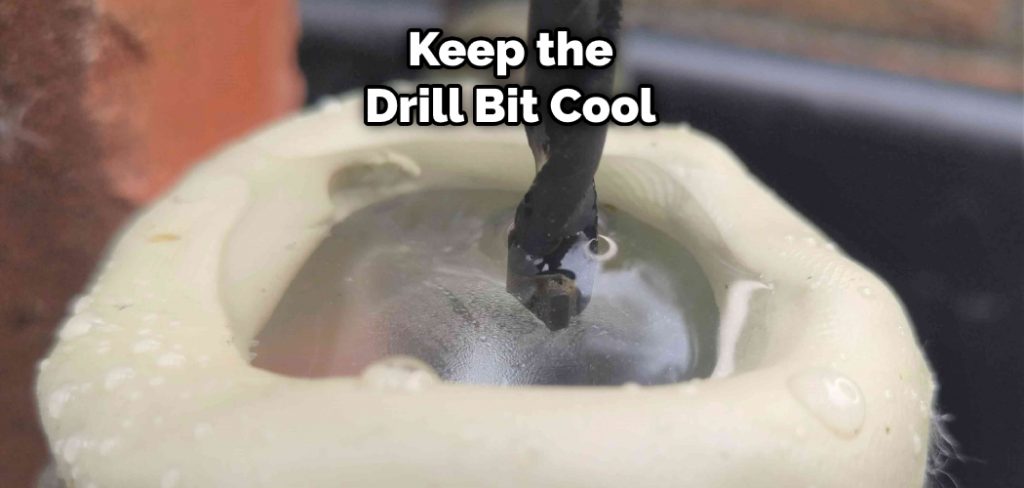

Using a sharp drill bit is important when drilling through the epoxy resin. A dull bit will cause the resin to heat up and could potentially cause it to catch fire. It is also important to go slowly when drilling and to use plenty of water to keep the drill bit cool.

Can You File Resin With a Nail File?

You can use a nail file to smooth the edges of your resin piece, but you cannot use it to make a this is because ae. A nail file will not create enough friction to drill through the resin.

If you don’t have a drill, there are several other ways you can make a hole in resin. For example, you can use a sharp object like a nail or a needle. You can also use a heated thing like a metal skewer.

FAQ

Can You Use a Hole Saw on Epoxy Resin?

There are a few factors that need to be taken into account. First and foremost, the type and hardness of the resin will play a role in whether or not a hole saw can be used on it. Secondly, the size and shape of the hole will also be important. Thirdly, the type of saw being used will also affect the outcome.

Generally, if the resin is soft or flexible, a hole saw can generally be used without any issues. If the resin is harder or more brittle, however, it may crack or shatter when cut with a hole saw. Finally, if a saw with a circular blade is being used, then it may not be able to make very deep cuts in the resin – this is because the blade tends to wander off course when cutting.

In short, while it is possible to use a hole saw on epoxy resin, there are some precautions that must be taken into account in order to avoid damage.

What Epoxy Can Be Drilled and Tapped?

Epoxy is a type of adhesive that is most commonly used to seal cracks and joints in concrete, wood, metal, and other similar materials. Epoxy can also be drilled and tapped, which makes it a versatile tool for construction. Here are a few tips on how to use epoxy to your advantage:

1. Epoxy can be used to seal cracks in concrete, which will prevent water and other contaminants from entering the structure.

2. Epoxy can be used as a joint sealant for wood decks, fences, and other wooden surfaces.

3. Epoxy can be used to repair metal damage caused by weathering or corrosion.

4. Epoxy can also be used to create custom seals for plumbing systems and equipment.

Can You Sand Resin?

Yes, you can sand resin with a sandpaper. Make sure to use a light touch and avoid over-sanding the surface as this could cause damage or scratching. If needed, repeat the process of wetting down the area then applying your sand paper until you have achieved the desired result.

Does Sanding Resin Scratch It?

It depends on the type of sanding resin that you are using and the extent of the scratches. Some resins may only scratch the surface while others may cause deeper damage. If you’re not sure whether your resin will cause scratches, test a small area first before applying it to your entire project.

Conclusion

If you’re looking for an easy way to make a hole in resin, you can try a few methods. All of them involve using something sharp to create a hole in the surface of the resin. Once the hole is made, you can use a straw or other object to blow into the hole and create the desired effect.

After reading this article on how to make a hole in resin without a drill, give one of these methods a try and see how it works for you. Have you ever tried making a hole in resin? What method did you use?