Curved pergola beams are structural components that create an attractive outdoor living space. They can be made from wood, metal, or PVC and give any patio, deck, or garden area a more finished look. The key to making curved pergola beams is to use the correct materials and techniques for cutting and joining the pieces together.

The main advantage of making curved pergola beams is that it adds a unique visual element to the structure and provides greater support for heavier loads. The curved beam design makes it more aesthetically pleasing than traditional straight beams while still providing the necessary strength and durability.

Because the curves can be customized to fit almost any design aesthetic, it makes for a great choice when trying to create a more customized look. In this blog post, You will learn in detail how to make curved pergola beams.

Tools You Will Need

- An angle grinder with a diamond blade.

- Eye and ear protection

- A measuring tape

- Circular saw with a blade that can cut curves

- Plywood or other material for the pergola beams

- A jig saw

- Sander

- Drill and drill bits

Step-by-Step Processes for How to Make Curved Pergola Beams

Step 1: Inspect the Pergola Beams

Before starting the project, inspect the pergola beams to ensure they are in good condition and free of any cracks or blemishes. Using a tape measure, measure how long you want your curve to be on each beam. Make sure to use the same measurements on each beam to be the same shape.

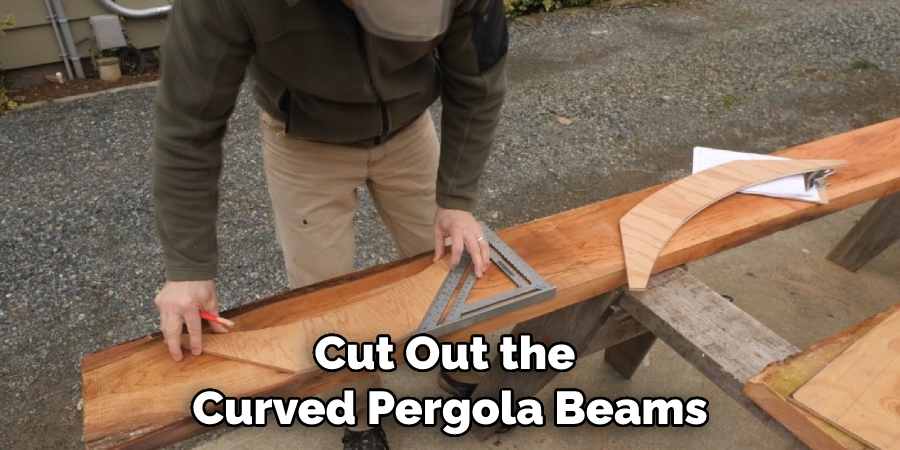

Step 2: Cut Out the Curved Pergola Beams

Using a jigsaw, cut out the curved pergola beams according to your measurements. Make sure you make clean cuts by using a steady hand and following a straight line. If needed, use sandpaper to smooth out any rough edges. Use a sander to sand down the sides of the curved pergola beams. This will help ensure that the curves are even and consistent across your beams.

Step 3: Measure and Mark the Curved Pergola Beams

Using a tape measure, measure, and mark where you want your screws to be placed on the curved pergola beams. Make sure the measurements are consistent across all of the beams for consistency. You can also use a pencil to make small notches in the wood to help guide you when drilling.

Step 4: Drill Pilot Holes in The Curved Pergola Beams

Using a drill and the right-sized bit, drill pilot holes into each curved pergola beam where you marked it with your measurements. Make sure not to drill too deep so that the screws don’t pierce through the other side of the wood.

Step 5: Attach the Curved Pergola Beams Together

Use some screws to attach the curved pergola beams together. Make sure you have enough screws and that they are long enough to go through both pieces of wood. Also, make sure that the screws are secure and don’t wobble. Use some wood glue to attach the curved pergola beams together. You should try each piece to have a generous amount of glue so that they stay put when they are attached.

Step 6: Allow the Curved Pergola Beams to Dry

After applying the glue and screws, allow the curved pergola beams to dry. Ensure that you keep them indoors and away from any moisture until they are completely dry. Once the curved pergola beams are dry, you can either stain or paint them to give them a finished look.

Finally, install the curved pergola beams onto the posts. Make sure to use a level so that they are even, and secure them with screws and bolts. Once installed, your pergola will be ready to enjoy.

Tips for How to Make Curved Pergola Beams

- Wear protective gear such as safety glasses, gloves, and a dust mask when working with power tools or saws.

- Ensure that you have reliable support for the beams while cutting them to size, as they may be unstable due to their flexibility.

- Ensure all your measurements are accurate to ensure a good fit for the pergola.

- Make sure that your cutting tools are sharp and in proper working order. Dull or damaged blades can cause slips, injuries, and inaccurate cuts.

- Use clamps to hold the beams in place while you work, so they don’t slide out of position while being cut or drilled.

- Secure the beams to the pergola framework with screws, nails, or bolts for additional stability.

- Test fit the beams before putting in the screws or nails to ensure everything lines up perfectly and fits snugly.

Following these tips will ensure your safety while working on How to Make Curved Pergola Beams.

What is the Best Way to Join the Beams Together?

One of the best ways to join curved pergola beams together is with a trench splice. This type of joint creates a strong and secure connection between the two pieces of wood while allowing for some flexibility in their movement. To make a trench splice, you need to cut an angled groove into both pieces of wood that will be joined.

Position the two pieces so that the grooves fit together snugly, then use metal hardware to hold them in place. You can also use screws and construction adhesive for added support. Ensure all the hardware is securely fastened, and then cover any exposed areas with putty or caulking to protect against moisture damage. With this method, your curved pergola beams will securely and safely join together.

How Much Time Will It Take to Construct a Curved Pergola From Start to Finish?

Constructing a curved pergola can take anywhere between one and several days, depending on the complexity of your design and the number of materials required. For example, constructing an elaborate pergola with multiple curved beams supported by multiple posts could take two to three days to complete.

On the other hand, building a basic pergola with only one curved beam and two posts could take a matter of hours. Ultimately, the amount of time required to construct a curved pergola will depend on your skill level and dedication to completing the project.

Additionally, these factors can increase the required time if you need extra help or materials. Regardless, constructing a curved pergola is well worth the effort because the end result will be a beautiful, stylish addition to your outdoor living area. With some patience and planning, you can create an attractive and enduring feature in your backyard that you can enjoy for years to come.

Why Should You Hire a Professional?

Making curved pergola beams is a complex job requiring specialized knowledge and skills. Even if you are an experienced woodworker, trying this project on your own is usually not recommended. Instead, it is wise to hire a professional with the right tools and experience to complete the job correctly and safely.

A professional contractor can help you create the perfect design and ensure that everything is properly installed. They will also be able to advise on the best materials to use and any other details necessary for a successful result. Hiring a professional ensures quality work and peace of mind knowing that your curved pergola beams are securely installed and constructed with the highest of standards.

By doing so, you can rest assured that your pergola will last many years and provide an attractive and inviting outdoor living space. Don’t take any chances when it comes to constructing curved pergola beams; hire a professional to ensure a successful outcome. With their experience and expertise, you can be certain that your pergola will look beautiful for years to come.

How Much Will It Cost to Make Curved Pergola Beams?

Making curved pergola beams can quickly become an expensive endeavor. The price of materials and labor needed to construct the beams will depend on several factors, such as the size and complexity of the structure, the number of poles required, and the overall design. It’s important to research all your options before making any commitments to ensure you’re getting the most bang for your buck.

Generally, curved pergola beams cost an average of $75 to $400 per linear foot to build, with the price increasing as complexity increases. The cost of materials alone can range from $25–$40 per linear foot. Labor costs will depend on the specific job and the contractor; they typically run between $50 and $200 per linear foot.

Conclusion

One of the main disadvantages of creating curved pergola beams is the complexity and difficulty involved in properly constructing such an intricate design. When compared to other, more traditional woodworking projects, building a curved pergola beam can be far more difficult due to its precise angles and measurements that must be taken into account.

Additionally, unlike other woodworking projects that can be made from pre-cut lumber, curved beams must usually be custom-made to fit the shape and size of the desired pergola.

Constructing curved pergola beams is the amount of time that can be necessary for this task. Since all measurements must be precise, a great deal of time must be taken to properly construct each beam to ensure that it fits properly and is aesthetically pleasing. I hope this article has been beneficial in learning how to make curved pergola beams. Make Sure the precautionary measures are followed chronologically.

You Can Check It Out to Attach a Pergola to A Deck