Do you have a plywood project that has sprung a leak, leaving behind tear-out and splintering wood? This kind of damage is not only unsightly but can also make your projects feel incomplete. Have no fear, though—with some simple steps on how to fix plywood tearout, and the right tools and techniques, you can easily fix any accidental wood splintering and make your project look as good as new.

You’ll be able to fix the tear out and keep working on your project in no time! Read on for tips and instructions on how to repair this common issue with plywood.

The Reasons Behind Plywood Tearout

1. Dull Saw Blades

The blades of saws become dull over time, and when you’re working with plywood, this can lead to a lot of tear-out. This is especially true if the wood is old or wet. Invest in sharp saw blades so that your cuts are precise and clean.

2. Incorrect Feed Direction

You should always feed the plywood into the saw in the direction of the blade’s rotation. If you push it against its rotation, it can cause splintering and tear out.

3. Incorrect Cutting Angle

If your cutting angle is off, it can create an uneven surface on the wood, which will lead to tearing and splintering. Be sure to use the right cutting angle and make sure that it matches up with your saw’s blade rotation.

Required Items to Fix Plywood Tearout

- Sandpaper

- Putty Knife or Spatula

- Epoxy Resin Filler

10 Instructions on How to Fix Plywood Tearout

1. Sanding

Sanding is one of the best ways to smooth out any rough or splintered edges created by plywood tear-out. Start with a medium-grit sandpaper and work your way up to finer grades for a smoother finish.

2. Filling

If the trout is deep, you may need to fill it with an epoxy resin filler. This can be found at most hardware stores and comes in premixed or powder form. Apply the epoxy with a putty knife or spatula and let it dry.

3. Smoothing

Once the filler is dry, use a sanding block to smooth out any irregularities. This will ensure that the surface of your plywood is even and free of splinters or rough patches when you’re done.

4. Finishing Touches

If you want to add a more polished look, you can use a wood stain or paint to match the color of the surrounding wood. Always test on a scrap piece of wood first and apply in thin coats.

5. Cleaning

Clean off any dust or debris from sanding with a damp cloth before applying the stain or paint. This will ensure that your project looks its best when it’s finished. Cleaning the dirt off the wood will also prevent any additional tearing or splintering.

6. Applying Sealant

Once you’ve finished staining and painting your project, it’s important to apply a sealant. This will protect the wood from moisture and other elements that could cause damage over time. It will also help your project last longer.

7. Letting it Dry

Once you’ve finished applying the sealant, let it dry completely before handling the wood again. This will ensure that the sealant has properly bonded with the wood and will provide a strong protective coat for your project.

8. Final Touches

For the final touches, use fine-grit sandpaper to smooth out any rough edges and make sure that the surface of your project is free of splinters or bumps. Final touches also include buffing the surface with a soft cloth to make it shine.

9. Checking for Quality

Before you call your project complete, take some time to inspect the wood for signs of tear-out or splintering so that you can address any issues before they become bigger problems. The quality of your project depends on it.

10. Enjoy Your Work!

You’ve now successfully repaired the plywood tear-out, and your project is ready to go. Take a moment to admire your hard work before you move on to the next project! You’ll be proud of what you’ve accomplished.

Finally, keep in mind that if you find yourself regularly dealing with plywood tear-out, investing in higher-quality plywood can be helpful. Good quality plywood is less prone to splintering and will save you time in the long run.

8 Safety Precautions to Take When Fixing Plywood Tearout

When it comes to how to fix plywood tearout, safety must always be a top priority. Here are eight tips for keeping you and the surface of your plywood safe while making repairs:

1. Wear protective gear when working with power tools such as a router, drill, or saw. This includes wearing safety goggles, a dust mask, and gloves to avoid any bodily harm from flying debris or sharp splinters of wood.

2. Disconnect the power source for all tools before making changes to the blades or adjusting settings on the router table. Keep your hands away from moving parts at all times. Disconnecting the power source also prevents any accidental starts of running machines.

3. Double-check all measurements before making a cut to ensure that the router bit is set at the proper depth for cutting into your workpiece. A deeper cut can cause more tear-out, whereas a shallow cut may not help fix the problem. When in doubt, make a test cut on a separate piece of scrap wood before tackling the actual repair.

4. When routing, make sure to move the router in a consistent direction and at an even speed. This helps keep the router bit from wandering and cutting into your workpiece too deeply, which can cause more tear-out.

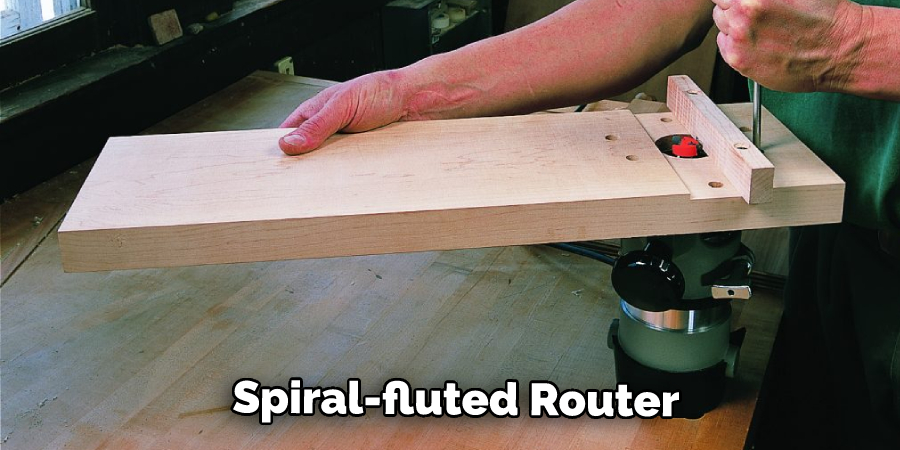

5. Select the right type of bit for the job. For plywood, a straight router bit with small carbide teeth is best for most applications. If you don’t have a straight router bit, another option is to use a spiral-fluted router bit with a larger diameter.

6. Take breaks and keep the work area well-ventilated. When working with power tools, wood dust can accumulate in the air and create an unhealthy environment, so make sure you take all necessary precautions, like using a dust collector or a mask.

7. Don’t rush the repair project. Take your time and work with precision to avoid any mistakes that could create more tear-out when fixing plywood surfaces.

8. When in doubt, seek professional help from an experienced woodworker or carpenter. It’s better to be safe than sorry when it comes to making repairs on plywood surfaces.

By following these tips for how to fix plywood tearout, you can work smarter and stay safe while getting the job done. With a little patience and attention to detail, you’ll have your plywood surface looking like new in no time!

Frequently Asked Questions

How Long Will It Take to Finish the Project?

The amount of time it takes to fix a plywood tear-out depends on the size and severity of the damage. Generally, a small repair should only take up to an hour or two, while larger repairs may require several days’ worth of work. It also depends on the skill level of the person doing the repair work.

What Are Some Good Tips for Avoiding Plywood Tearout?

The key to avoiding plywood tear-out is to take your time and make sure all measurements are correct before making any cuts. Furthermore, using the right type of router bit and setting it at a proper depth can help minimize tear-out.

Additionally, a spiral-fluted router bit is also helpful for cutting smoother edges and helping to keep the tear-out to a minimum. It will also help to use a sharp blade and move the router in a consistent direction with an even speed.

What Can I Use to Help Fix Plywood Tearout?

To fix plywood tear-out, you’ll need some type of power tool, such as a drill, router, or saw. You’ll also need clamps to secure the workpiece in place and a router bit with small carbide teeth for making the repair cuts. Additionally, it may also be helpful to use a spiral-fluted router bit for smoother edges. Lastly, make sure you have protective gear such as safety goggles, a dust mask, and gloves to stay safe while working.

Following these steps should help you fix your plywood tear-out without any major issues. With some patience and attention to detail, you’ll be able to get the job done right!

Conclusion

Plywood tear-out is a common problem when woodworking, but thankfully it can be fixed easily with some preparation, the right tools and materials, and carefully applied techniques. With a little knowledge of the issue and how to fix it, plywood tear-out won’t have to frustrate your projects any longer.

Whether you’re an experienced woodworker or just starting out in the world of DIY, you now have the information needed to fix plywood tear-out quickly and correctly. Plywood doesn’t have to be your enemy–with proper planning and understanding, you can use tutorial tools and wooden projects in confidence, knowing that with these steps on how to fix plywood tearout you can repair plywood tear-out whenever it occurs.