Ship lap has become a popular trend in home design, but it can be tricky to get the corners just right. When it comes to home decor, certain elements are always in style. Shiplap is one of those elements. It adds a touch of rustic charm to any room. Like me, you probably associate shiplap with rustic farmhouses and sleek, modern homes.

But what do you do when your space calls for something in between? What do you do if your walls aren’t relatively straight? How do you meet corners with shiplap? Don’t worry; I have all the answers on how to end shiplap on an outside corner! Keep reading to learn how to create a seamless look with shiplap.

14 Methods on How to End Shiplap on an Outside Corner

If you’re wondering how to end shiplap on an outside corner, there are a few different methods you can use. Here are 15 ways with details on how to achieve each one.

1. Use a Miter Saw

If you have a miter saw, you can use it to cut your shiplap at an angle so that it fits perfectly on your outside corner. Then, measure the curves of your intersection, adjust your miter saw accordingly, and make your cuts. This method will give you a clean, polished look, but it may take some practice to get the angles just right.

2. Use a Circular Saw

If you don’t have a miter saw, you can use a circular saw to make the same cuts. Just be sure to use a guide so that your cuts are straight. This method may take a bit more precision and patience, but it can still result in a seamless finish. You can also use a jigsaw or handsaw if you don’t have access to a circular saw. It may take more time and effort, but the end result will be worth it.

3. Use a Jigsaw

You can use a jigsaw to cut the ends of your shiplap boards at an outside corner. This is a great option if you want to avoid using a miter saw or a power saw. Simply mark the line where you need to cut, and then use a jigsaw to follow the line and make the cuts. This method may take a bit more time and precision, but it can still result in a clean finish. You can also use a handsaw if you don’t have access to a jigsaw.

4. Use a Hand Saw

You can use a hand saw if you don’t have a miter saw. Just be careful to ensure your cuts are straight of shiplap at a 45-degree angle. This will allow the two pieces of shiplap to meet seamlessly. This method may take the most time and effort, but it is still doable if you have patience and a steady hand. There are even handsaws specifically designed for cutting at angles, which may make the process easier.

5. Use a Chisel

If you’re working with a natural wood shiplap, you can use a chisel to create a rabbeted edge on one side of the boards. This will allow the panels to fit snugly against each other on your outside corner. Be sure to use a sharp chisel and take your time for the best results. Otherwise, you may end up with a jagged or uneven edge.

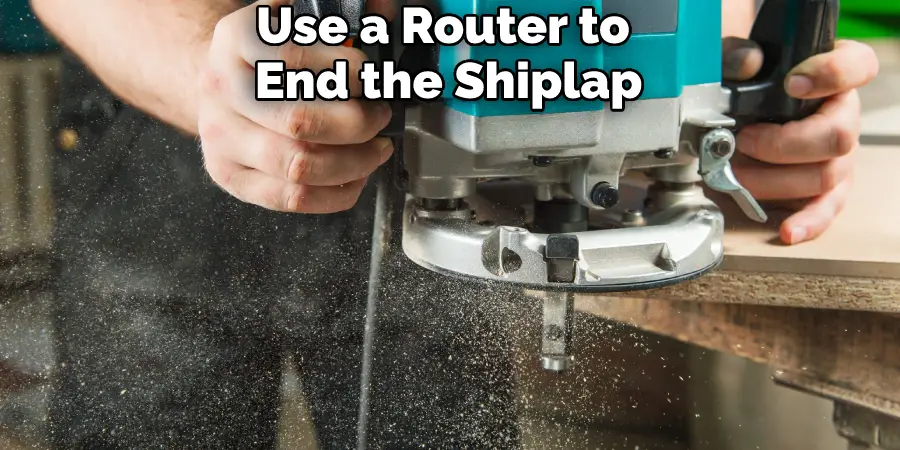

6. Use a Router

You can use a router to end the shiplap on an outside corner if you want a more polished look. This will give your project a cleaner and more professional appearance. To do this, you’ll need to make a few passes with the router, gradually increasing the depth of the cuts. Begin with a shallow cut and then make deeper cuts until you reach the desired depth. This method may require some practice to get the hang of using a router, but it can result in a seamless finish. Remember to use a router bit that is the same width as your shiplap boards for a seamless look.

7. Use Trim

You can use a trim that is about 1/8″ wider than the shiplap boards. This will give you a little leeway when it comes to fitting the trim around the corner. You can either miter or butt the trim up against the shiplap. If you choose to miter, be sure to make the correct angle cuts on both the inside and outside corners for a polished look. If you choose to butt up against the shiplap, it may result in a more rustic appearance. The choice is yours! Either way, this method will cover any gaps or imperfections on the corners and give your project a finished look.

8. Use a Scarf Joint

You can use a scarf joint to end your shiplap on an outside corner. To make a scarf joint, simply cut a 45-degree angle on each end of your boards. Then, fit the boards together and secure them with nails or screws. You can also use wood glue to help hold the scarf joint together. This method will result in a strong and seamless corner that is less likely to separate or show gaps over time.

You can use trim to cover up the scarf joint if you want a more finished look. Just add some trim around the outside corner and paint or stain it to match your shiplap.

9. Use a Butt Joint

If you’re not concerned about having a seamless finish, you can use a butt joint to join the boards on your outside corner. This is the easiest way to join the panels, but it will leave a small gap where the boards meet. You can use wood filler to cover up the gap and create a smooth surface before painting or staining. This method may not be as visually appealing as other options, but it is still a viable choice.

10. Use a Tongue and Groove Joint

Using natural wood shiplap, you can use a tongue and groove joint to join the boards on your outside corner. This is a more advanced technique, but it will give you a seamless finish. To create a tongue and groove joint, you’ll need to cut a tongue on one end of each board and a corresponding groove on the other. Then, fit the boards together and secure them with nails or screws. It may take some practice to get the cuts just right, but it can result in a professional-looking finish.

11. Use a Beadboard

You can use beadboard if you want to add a decorative touch to your outside corner. You can either nail or screw the beadboard into place. Use waterproof sealant or caulk at the joints to prevent water damage. Beadboard is a great option for those looking to add some texture and interest to their shiplap project.

Once you have decided on the method that works best for your situation, it’s time to start installing your shiplap! Remember to measure and mark your cuts carefully, using a level to ensure your boards are straight. And don’t be afraid to take your time and make adjustments as needed for the best results.

12. Use a V-groove

Another option for adding a decorative touch to your outside corner is to use a V-groove. This is a more advanced technique, but it will give you a professional-looking finish. Also, it will provide you with a clean, finished look. To create a v-groove, you’ll need to cut a groove on one end of each board and a corresponding tongue on the other. Then, fit the boards together and secure them with nails or screws. This method may take some practice to get the cuts just right, but it can result in a seamless and polished finish.

13. Use Wainscoting

If you want to add a touch of elegance to your outside corner, you can use wainscoting. You can either nail or screw the wainscoting into place. Use waterproof sealant or caulk at the joints to prevent water damage. Wainscoting is a great option for those looking to add a touch of sophistication and style to their shiplap project. It can also provide added protection against moisture or other environmental factors.

14. Use a Picture Frame

If you want to add a touch of style to your outside corner, you can use a picture frame. You can either nail or screw the picture frame into place. Use waterproof sealant or caulk at the joints to prevent water damage. Adding a picture frame to your shiplap project can give it a unique and personalized look.

No matter which method you choose, measure twice and cut once so your shiplap fits perfectly on your outside corner.

What Do You Need to End Shiplap on an Outside Corner?

If you’re finishing a shiplap wall and need to end it on an outside corner, there are a few tools you’ll need to get the job done.

First, you’ll need a saw to cut the boards to the correct length. You’ll also need a level to ensure your cuts are straight and a hammer and nails to attach the panels to the wall.

To start, measure the wall length from the corner to where you want the shiplap to end. Next, cut your boards to this length, making sure to use a saw that can cut through the material you’re using for your shiplap. Once you have all your boards cut, lay them out on the ground and arrange them in the order you want them to go on the wall.

Starting at the bottom, nail each board into place, making sure to use a level to keep your boards straight. Then, using natural wood shiplap, you can also use a finishing nailer to attach the panels. Once all the boards are in place, you can add any trim or molding you want to cover up the edges.

Now you know how to end shiplap on an outside corner. With the right tools and effort, you can create a beautiful and professional-looking finish for your wall.

Do You Need to Get Help From Experts?

Consider hiring a professional contractor to help you with your shiplap installation if you do not feel comfortable tackling the project on your own. Installing shiplap may seem straightforward, but it can be a challenging task that requires precise measurements and cuts to achieve a polished look. A professional contractor will have the necessary tools and experience to ensure that your shiplap is properly installed and finished on outside corners.

Additionally, contracting a professional can save you time and stress, especially if you have limited DIY skills or a busy schedule. It may also be beneficial to consult with an expert about the best materials and techniques for ending shiplap on outside corners for your specific project.

Ultimately, the decision to seek help from experts will depend on your level of comfort and experience with home improvement projects. If you’re unsure, it’s always better to err on the side of caution and hire a professional for a job well done. So, it’s important to assess your own abilities and determine if you can handle the project on your own or if you should seek outside help.

Things You Need to Keep in Mind Before Ending Shiplap on an Outside Corner

1. Always use finished nails when securing the last piece of shiplap on an outside corner rather than common nails. This is because finish nails have a smaller head and won’t mar the surface as quickly as common nails.

2. When making cuts for the final piece, always err on making the amount too small rather than too large. You can always sand down a piece that’s too small, but it’s tough to make a bit larger.

3. Make sure the final piece is well-secured before moving on to the next project. The last thing you want is your shiplap to lose after finishing everything else.

4. If you’re using a power saw to make your cuts, be extra careful not to damage the surface of the shiplap. A small nick can easily ruin the whole piece.

5. It’s always a good idea to test fit the final piece before making any cuts. This way, you can make sure everything will fit together perfectly before you make any irreversible mistakes.

6. When sanding the final piece, use fantastic grit sandpaper. You don’t want to damage the surface of the shiplap by using a too-coarse grit.

7. Once you’ve finished sanding, apply a clear sealer to the shiplap to protect it from the elements.

8. If you’re painting the shiplap, use high-quality exterior paint. Cheap paint will chip and peel easily, and it won’t look nearly as good as a higher-quality product.

9. Make sure you allow the paint to dry completely before applying the final coat of sealer. Otherwise, you risk the paint peeling off down the road.

10. Once everything is dry, apply a final coat of clear sealer to the shiplap. This will help protect it from the elements and keep it looking its best for years.

By following these simple things, you can be sure your shiplap will look great for years to come. So don’t be afraid to tackle this project yourself – it’s not as difficult as it may seem!

Frequently Asked Questions:

Q: Can I Use Shiplap on an Outside Corner?

A: Yes, you can definitely use shiplap on an outside corner. It’s a great way to add texture and dimension to your walls while also protecting them from the elements.

Q: What Tools Do I Need to End Shiplap on an Outside Corner?

A: To end shiplap on an outside corner, you’ll need a saw, level, hammer and nails. You may also want to use a finishing nailer if using natural wood shiplap.

Q: Is It Difficult to End Shiplap on an Outside Corner?

A: It can be a little more challenging to end shiplap on an outside corner, but with the right tools and techniques, it’s definitely doable for any DIY enthusiast.

Q: How Do I Seal Shiplap on an Outside Corner?

A: To seal the shiplap on an outside corner, you can use waterproof sealant or caulk at the joints to prevent water damage. You can also apply a clear sealer to protect the shiplap from the elements.

Q: Can I Use Shiplap to Cover an Entire Wall?

A: Yes, you can use shiplap to cover a full wall, half wall, or even just as an accent piece. It’s a versatile and stylish option for adding depth and visual interest to any room in your home. So don’t be afraid to get creative with it! Just make sure to properly measure and plan before starting your project.

Overall, shiplap is a great way to give any wall or corner a finished and polished look. Whether you’re using it indoors or outdoors, with the right tools and techniques, you can achieve a professional-looking result that will last for years to come. So go ahead and give it a try – you might just surprise yourself with your DIY skills!

Conclusion

Shiplap is a popular trend in home design and can be used to add visual interest and texture to any space. It is a great way to add character and charm to your home, but it can be tricky to get the ends just right. With these methods, you’ll be able to finish shiplap on an outside corner like a pro in no time!

This post showed you how to end shiplap on an outside corner for a clean, polished look. Have you tried using shiplap in your own home? Let us know what you think in the comments below!