Are you looking for a quick and easy way to add texture and depth to your walls, floors, and ceilings? Tongue-and-groove is the perfect solution! With its interlocking joints that make it simple to install and exceptionally strong once in place, tongue-and-groove construction is an effective choice for achieving a beautiful look without sacrificing quality or durability.

Whether you’re installing tongue-and-groove on your own or with help from a professional installer, the process is the same. Here’s what you need to know about how to cut tongue and groove.

In this article, we’ll provide you with step by step instructions on how to cut classic tongue-and groove boards so that you can complete your project!

What Will You Need?

Before getting started, it’s important to ensure you have all the necessary tools and materials. Here’s a list of what you need to cut tongue-and-groove boards:

- Tongue and groove planks

- Tape measure

- Pencil or pen

- Miter saw (or circular saw)

- Table saw

- Chisel

- Hammer

Once you have all the materials ready, you’re good to go!

10 Easy Steps on How to Cut Tongue and Groove

Step 1: Measure and Mark Your Boards

Before cutting, take the time to measure and mark your boards. This will ensure that you get perfectly straight lines when joining the boards. You should use a tape measure and pencil or pen to ensure accurate measurements.

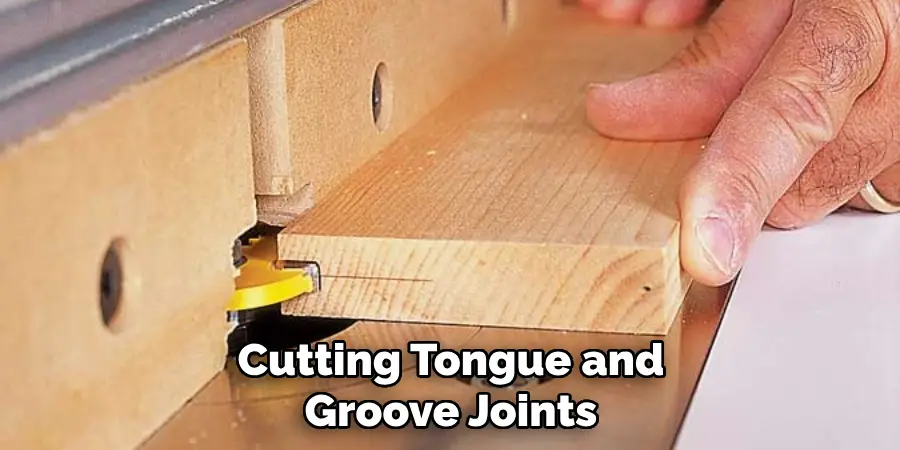

Step 2: Cut the Tongue

Once you’ve marked your boards, it’s time to start cutting. You should start by cutting the tongue off one end of each board using a miter or circular saw. Make sure that your cuts are straight and even so that the tongue will fit properly when the boards are joined together.

Step 3: Measure and Mark the Groove

Next, you’ll need to measure and mark the groove on the other end of each board. You should use a tape measure and pencil or pen to ensure accurate measurements. Be careful not to cut too deep into the board; you don’t want to compromise its structural integrity.

Step 4: Cut Out the Groove

Once you’ve marked the board, it’s time to cut out the groove. You can use a table saw for this step or a chisel and hammer if you prefer. Make sure that your cuts are straight and even so that the tongues will fit properly when the boards are joined together.

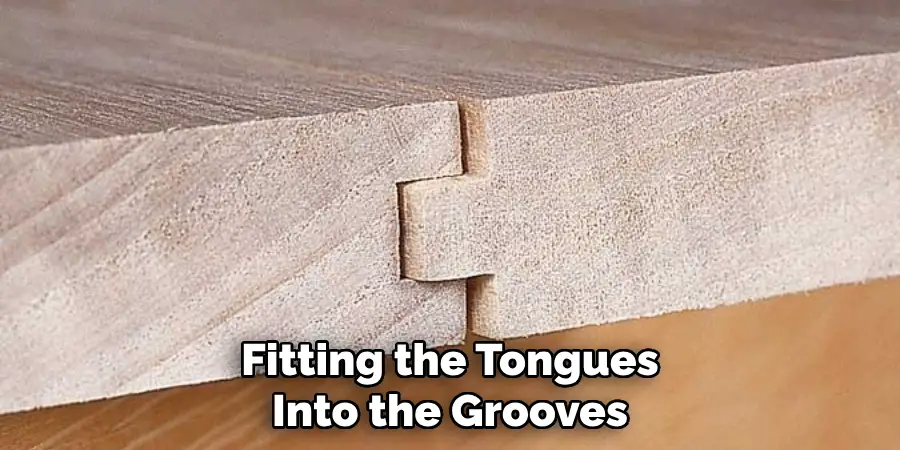

Step 5: Fit Together the Boards

Now it’s time to fit the boards together. You should start by fitting the tongues into the grooves and make sure that they are correctly aligned before hammering them into place. Ensure not to drive in too many nails, as this can damage or weaken the joints.

Step 6: Check Your Measurements

Once the boards are fitted together, take the time to double check your measurements. This is important because even small discrepancies in the joint can lead to an uneven finished product. Additionally, make sure that the boards are securely in place.

Step 7: Sand and Fill Gaps

After the boards have been fitted together, you’ll need to sand any rough edges and fill in any gaps between the boards. This can be done with a hand sander or sandpaper and wood filler. If using a hand sander, make sure to use a light touch and keep the sander moving in order to avoid damaging the wood.

Step 8: Seal the Joints

Once you’ve filled any gaps, it’s time to seal the joints. This is important because it will prevent moisture from getting into the wood and causing warping or splitting over time. You can use a waterproof sealant or wood glue to do this step, but make sure that the product you choose is suitable for the material of your boards.

Step 9: Paint or Stain the Boards

Once you’ve sealed the joints, it’s time to paint or stain your boards. This will give them a professional look and help protect them from weathering. You can use a brush to do this step or a sprayer for larger projects. Make sure to take your time and apply an even coat of paint or stain.

Step 10: Install the Boards

Finally, you’re ready to install the boards! Depending on the type of tongue-and-groove you’re using, this step can be as simple as nailing the boards to a wall or floor. Alternatively, you may need to use construction adhesive for more complex projects. Remember to take your time and make sure that the boards are securely in place before you move on.

By following these steps, you’ll be able to cut and install tongue-and-groove boards quickly and easily. With its unique look and strength, tongue-and-groove can add texture and depth to your walls, floors, and ceilings in no time. Now all that’s left is to get started on your project!

5 Additional Tips and Tricks

- Ensure Your Tools are Sharp: When cutting tongue and groove joints, it’s essential that your cutting tools, such as your table saw blade or router bit, are sharp. This helps to make the cut cleaner and more precise.

- Use a Feather Board: A feather board is a safety device when cutting wood on a table saw or router table. It helps to keep the workpiece steady and prevents kickback, making your cutting task safer and more accurate.

- Measure Twice, Cut Once: This old saying is particularly true when cutting tongue and groove joints. Double-check your measurements before making each cut to ensure accuracy and prevent waste.

- Dry Fitting is Essential: Always dry-fit your pieces together before applying any glue. This will help you to identify any issues with the fit and make adjustments as necessary.

- Don’t Rush the Glue Up: When you’re ready to assemble your project, take your time to apply the adhesive neatly and ensure all surfaces are fully coated. Also, be patient and allow the glue to dry fully before moving on to the next stage.

With these tips, you can now easily and confidently cut tongue and groove joints. Taking the time to ensure your tools are sharp, using a feather board for safety, double-checking your measurements, dry-fitting pieces together before gluing them up, and not rushing the glue-up process will help you achieve perfect results every single time.

5 Things You Should Avoid

- Avoid Using Dull Tools: Dull tools not only make your work harder but can also lead to inaccuracies in your cuts. Moreover, they can cause the wood to splinter or tear, ruining the quality of your tongue and groove joints.

- Remember Safety: Pay attention to the importance of safety when working with power tools. Always wear suitable safety gear such as safety glasses, hearing protection, and a dust mask.

- Avoid Guesswork: Don’t estimate measurements or angles when cutting tongue and groove joints. Precise measurements are crucial to achieving a perfect fit.

- Only Glue With Checking: Avoid gluing your pieces together without first checking the fit. Problems are much easier to fix before the glue is applied.

- Avoid Rushing: Woodworking projects, particularly ones involving intricate cuts like tongue and groove, require patience and attention to detail. Rushing through the process can lead to errors and inferior results.

Avoiding these common mistakes will help you get the best results when cutting tongue and groove joints. Taking your time to double-check measurements, use the right tools and wear safety gear, dry-fit each piece before gluing them up, and take your time with the process to ensure your project is a success.

Does Tongue and Groove Need Gap?

The answer is yes, tongue and groove joints should have a small gap. This helps to ensure the joint fits snugly without binding, as wood contracts and expands with seasonal changes in humidity. The size of this gap depends on the type of wood you’re using; softwoods such as pine usually require a larger gap than hardwoods like oak or walnut. Aim for a gap of 1/8 to 1/4 inch (3-6 mm).

When cutting tongue and groove joints, it’s important to bear this in mind. If the spacing is too tight or too loose, your joint won’t fit properly. For best results, always measure twice before making each cut.

Conclusion

All in all, cutting tongue and groove is less intimidating than many people might think. If you’re willing to invest the time and energy into researching the outlook and safety protocols and mastering the few essential steps, you can even tackle this job confidently. It’s a gratifying process that results in a beautiful, professional-looking finish.

If you’re tackling a small home project or seeking to make this skill part of your tradecraft, these tips should serve you well. If nothing else, they secure that initial knowledge base needed for any larger projects.

Hopefully, the article on how to cut tongue and groove has clarified the process and provided some helpful tips to get you started. With these pointers in mind, why not try cutting tongue and groove joints today? Good luck, and thanks for reading!