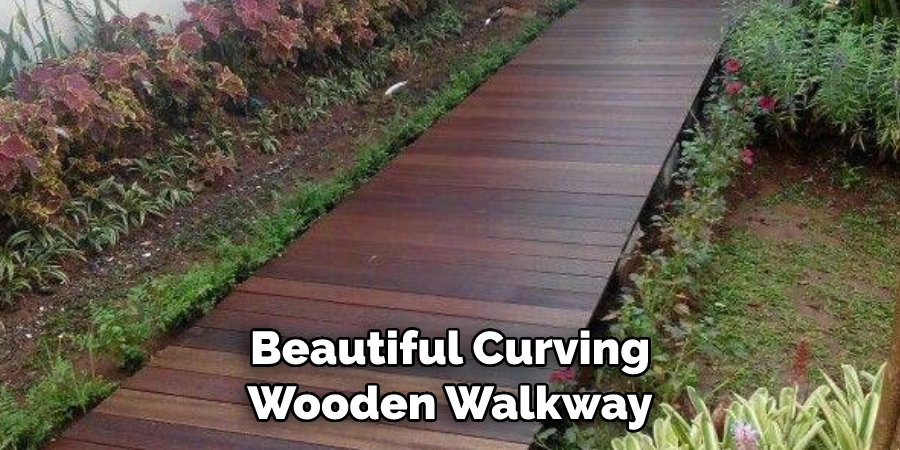

For many homeowners, creating the perfect walkway for their property can be a challenge. Curving paths add a layer of complexity to the process, requiring careful planning and astute attention to detail to get it just right. It is important to know how to build a curved wooden walkway. Building a curved wooden walkway is doable with the proper tools and materials—all you need are some solid wood boards, quality lumber pieces, and your imagination.

This blog post will provide step-by-step instructions on how to construct an attractive curved wooden walkway that’s sure to make heads turn as guests enter your home or backyard space! Keep reading for more details and tips on building your custom creation!

Tools You Will Need:

Hammer:

A hammer is an essential tool for building a curved wooden walkway. You will need it to drive in nails and secure the wood pieces together.

Measuring Tape:

Measuring tape is crucial for ensuring accuracy when cutting your wood boards to the correct size. It will also help you plan out the dimensions of your curved walkway.

Nails:

Nails are the most common fasteners used in woodworking projects. Make sure to use galvanized nails that won’t rust over time and compromise the structure of your walkway.

Circular Saw:

A circular saw is the main power tool that you will need to cut your wood boards. Make sure to use a blade suitable for cutting wood and always follow safety precautions while using this tool.

Leveler:

A leveler is essential for ensuring that your curved wooden walkway is even and flat. It will help you avoid any unevenness or bumps in the path, providing a smooth surface for walking.

Tape Measure:

In addition to a measuring tape, having a tape measure on hand will also come in handy for building your curved wooden walkway. It can be used for double-check

Framing Square:

A framing square is a useful tool for creating precise right angles and straight lines in your walkway design. It will help you ensure that your boards are cut at the correct angles and fit together seamlessly.

Jointer/shaper (Optional):

If you want to add decorative edges or curves to your wood boards, a jointer or shaper can be helpful. These power tools can create customized cuts and designs on your wood pieces, adding an extra touch of detail to your curved walkway.

Materials You Will Need:

Pressure-treated Lumber Pieces of Different Lengths:

To build a durable and long-lasting curved wooden walkway, it’s important to use pressure-treated lumber. This type of wood is treated with chemicals that make it resistant to rot, decay, and insect damage.

Solid Wood Boards:

Solid wood boards will be the main material used for your walkway. Choose a high-quality wood such as cedar or redwood for a beautiful and sturdy finished product.

Gravel:

Gravel is a necessary material for building a strong foundation for your walkway. It will provide drainage and stability, preventing the wood pieces from shifting or sinking over time.

Landscape Fabric:

Landscape fabric is used to prevent weeds from growing under your walkway and causing damage. It also helps with drainage and provides a barrier between the gravel and soil underneath.

Wood Sealer (Optional):

If you want to protect your walkway from weather damage and preserve its natural beauty, consider using a wood sealer. This will also help prevent splintering over time.

Top 10 Steps Guide on How to Build a Curved Wooden Walkway:

Step 1: Measure the Length and Width of Your Walkway

Taking the time to accurately measure the length and width of your walkway before building it is essential for success. Knowing these dimensions is vital, as they determine how many pieces of wood will be needed for each section. For a curved wooden walkway, aim to use 2×6 boards cut to match the measurements you have taken, ensuring that all pieces are perfectly fitted together.

As an example, if your walkway is 10 feet wide and 20 feet long then you would need two boards cut to 10 feet in length to construct it. When measuring the length and width of your proposed walkway keep in mind that errors can occur when converting inches into feet so always double-check! Once all necessary materials have been acquired and measurements are taken, it’s time to construct a beautiful, curving wooden walkway that will add value and charm to your exterior space.

Step 2: Cut the Boards for Each Section

If you’re planning to build a curved wooden walkway, it’s important to cut the boards for each section with precision. To ensure that the cuts are straight and level, use a circular saw or another wood-cutting tool. It may also be helpful to use a framing square when cutting the boards, as this will guarantee accuracy while assembling the structure.

As always, safety should be your number one priority – don’t forget to wear protective gear, such as earplugs, safety glasses, and work gloves. With these tips in mind, you’ll have everything you need to build a beautiful curved wooden walkway.

Step 3: Lay Out the Walkway

To begin laying out your curved wooden walkway, start by planning out where it will go in your garden. Taking measurements of both inside and outside corners is essential to ensure the walkway runs smoothly. Utilizing stakes or another type of temporary marking, map out how the pieces will all fit together with precise accuracy.

So that when you go to assemble each section your puzzle interlocks perfectly. Once you have laid out the dimensions for each piece and taken the measurements, you are now ready to start constructing your wooden walkway.

Step 4: Join the Wooden Boards Together

Joining the wooden boards together is a crucial step in the walkway-building process. Hammering the nails into each board provides strength and stability to your curved wooden walkway. For added security, it is recommended to alternate between two nails for each board when assembling them.

This means for every nail you place, you should place a second at a different angle, thereby creating an additional point of contact between the boards. With careful planning and execution in this step of the process, soon you will have a beautiful structure that can be enjoyed for many years to come!

Step 5: Cut Any Necessary Curves

Building a curved wooden walkway is a great way to add interest and appeal to your home or garden. To achieve an expert-looking result, you’ll need to make sure that any necessary curves are cut precisely and as evenly as possible.

The easiest way to do this is to use a circular saw. However, for even more accurate cuts, using a jointer or shaper tool will help you achieve the smooth edges and perfect levelness that you’re looking for. Put the extra effort in and the results will pay off; your work will be sure to impress!

Step 6: Attach the Boards to Your Walkway Framework

To attach the boards to your walkway framework, simply use deck screws and evenly distribute them along the perimeter of each board. Make sure that the screws are going all the way through every board and into the supporting beam beneath it.

It is important to securely attach all of your boards for safety reasons and to ensure that your walkway lasts for years to come. Take extra care when using power tools in this process. Always remember to use safety precautions such as wearing protective gear and disconnecting any equipment from the power source before attempting any repairs or modifications.

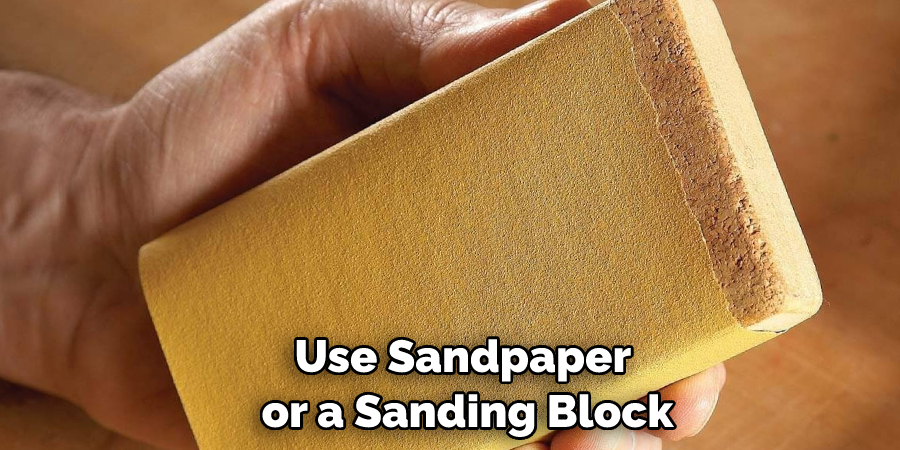

Step 7: Sand and Finish the Walkway’s Surface

Finally, use sandpaper or a sanding block to smooth out any rough spots on the surface of your walkway. You may also want to add a finish of your choice—stain, sealant, or paint can all be applied to protect the wood and give it an attractive look.

When sanding, be sure to get into all of the nooks and crannies between each board to ensure that the surface is smooth. This will also help prevent any splintering or rough edges that could cause injury when walking on your new curved wooden walkway.

Step 8: Lay Landscape Fabric

Laying landscape fabric is an optional but highly recommended step in building a curved wooden walkway. This fabric helps to prevent weeds and other plants from growing through the boards of your walkway, making for a more pleasing appearance and easier maintenance. It also helps to prevent any soil or debris from getting trapped between the boards, which could cause damage over time.

You can lay landscape fabric before or after attaching the boards, depending on your preference. Simply cut the fabric to fit the dimensions of your walkway and place it on top of the ground before laying down the boards. Trim any excess fabric if necessary. This simple step can go a long way in maintaining the beauty and functionality of your curved wooden walkway.

Step 9: Lay Gravel

After laying down landscape fabric, the next step is to lay gravel on top of it. This will help with drainage and provide a stable base for your walkway. Pour the gravel evenly along the entire length of your walkway, making sure it is level and no gaps or uneven spots. Use a rake to spread the gravel evenly if necessary.

The gravel can also add an aesthetic touch to your walkway, as there are many different colors and sizes available on the market. Consider choosing a color that complements the rest of your garden or outdoor space for a cohesive look.

Step 10: Enjoy Your New Curved Wooden Walkway!

Congratulations, you have successfully built a curved wooden walkway for your home or garden! Take pride in your hard work and enjoy the beauty and functionality that this structure brings to your outdoor space. With proper maintenance and care, your walkway will continue to provide years of use for you and your loved ones. Remember to regularly check for any signs of wear or damage and address them promptly to ensure the longevity of your project.

Always remember to prioritize safety when working with power tools or performing any home improvement projects. Follow all safety guidelines and seek professional assistance if needed. But most importantly, have fun and enjoy the fruits of your labor! Your curved wooden walkway is sure to be a highlight in your garden for years to come.

Do You Need Additional Inspiration or Assistance?

Building a curved wooden walkway can be a challenging but rewarding project. If you need additional inspiration or assistance, there are many resources available to help guide you through the process. Online tutorials, woodworking forums, and even local classes can provide valuable tips and advice for building your walkway.

Additionally, don’t be afraid to experiment with different designs or materials to create a unique look that fits your personal style and preferences. With the right tools, materials, and techniques, you can create a stunning curved wooden walkway that will enhance your outdoor space and impress any visitors.

How Much Could It Cost?

The cost of building a curved wooden walkway will vary depending on the size, materials used, and any additional features or designs. However, as a general estimation, it could cost anywhere from $500 to $1500 for materials alone.

As with any home improvement project, it is important to carefully plan and budget before beginning construction. Consider researching different options and prices for materials, as well as any tools or equipment that may be needed. By carefully considering costs and making informed decisions, you can build a beautiful curved wooden walkway without breaking the bank.

Additional Tips:

- Measure and Mark Your Boards Carefully Before Cutting to Ensure Accuracy.

- Use a Level to Make Sure Your Walkway is Even and Sloping Slightly Away From Your House for Proper Drainage.

- Regularly Check for Any Signs of Wear or Damage and Address Them Promptly to Prevent Further Issues.

- Consider Adding Lighting Fixtures Along the Sides of Your Walkway for Added Safety and Ambiance at Night.

- If You Are Unsure or Uncomfortable With Any Step of the Process, Seek Professional Assistance. Safety Should Always Be a Top Priority.

- Don’t Be Afraid to Get Creative With Your Design and Materials. Experiment With Different Types of Wood, Stains, or Finishes for a Unique Look.

- Regular Maintenance Can Help Prolong the Life of Your Walkway. Consider Reapplying a Protective Finish Every Few Years Depending on the Wear and Tear It Receives.

- Have Fun and Enjoy the Process! Building a Curved Wooden Walkway Can Be a Fun and Rewarding Project That Adds Both Beauty and Functionality to Your Outdoor Space. So Grab Your Tools and Get Building! Happy Walkway Constructing!

Frequently Asked Questions

How Do I Cut a Curved Shape in Wood?

Cutting curves in wood is not an impossible task, but it does require some extra preparation and the right tools. To achieve a precise cut, first, use a drill to make starter holes along the line you want to follow. Then, use an angle grinder with a grinding or cutting blade to make your curved cuts.

When starting, you may find it helpful to use a guide while cutting or sanding – such as a jig saw or band saw – so that you can easily keep your lines consistent and even. Lastly, before you make your final contour cuts, take the time to round off sharp edges for more accurate results. By following these steps, you can create professional-looking results in no time!

How Can I Ensure an Even Surface on My Wooden Walkway?

To create an even wooden walkway surface, preparation is key. Sand down any rough spots, ensuring that the entire length of the walkway feels smoother to the touch. Fill in any deep cracks with an appropriate filler substance and sand back down once it’s dried. Next, you’ll need to apply a base coat of sealant or shellac to ensure the finish coat will properly adhere to the walking surface.

Finally, for added protection, a UV-resistant finish coat can be applied topically – be sure to allow at least 24 hours between coats for proper drying and curing. By following these steps closely, you can achieve a perfectly smooth wooden walkway that will last for years.

Is It Best to Use Stain, Sealant, or Paint for a Protective Layer on the Wood?

Whether used for furnishings or exterior purposes, protecting the wood surfaces of your home requires careful consideration. Understanding which type of protective layer is best suited for a particular job is key if you are to ensure that the wood lasts for years to come. If the goal is to retain the natural look and texture of the wood, the stain would be the best option.

For exterior projects, such as fences or decks, sealant can provide texture while also protecting it from rain, snow, and sun damage. On smooth furniture surfaces, the paint might offer added protection. Ultimately, deciding what form of protection your wood needs depends on a combination of factors like its purpose and current level of wear.

Conclusion

By following these simple steps, you can create a beautiful and functional curved wooden walkway for your home. You should carefully determine how to build a curved wooden walkway. Not only will this be a great addition to your curb appeal, but it will also provide a safe and easy way for you and your family to get around your property. So what are you waiting for? Get started today!

You Can Check It Out to Build a Roof for a Gazebo