If you have ever tried to trim wood with a standard blade on a saw, you know it is not an easy task. The edges are usually rough and jagged, making the piece difficult to work with. This blog post will teach you how to trim wood edges using a specialty blade designed for this purpose. We will also show you some tips and tricks to help you get the job done quickly and efficiently. Let’s get started.

Summary: There’s no need to be a woodworker to know how to trim wood edges. All you need is a straight edge, a saw, and some basic safety precautions. Here’s how to do it: 1. Start by cutting a piece of wood that’s the same length as the desired edge. Make sure the wood is straight and the cut is clean. 2. Line up the edge of the saw with the edge of the wood, and position the blade so that it’s touching the wood. 3. Push down on the saw handle, and start sawing the wood away from the edge. Hold the wood firmly with one hand, and use the other hand to guide the cut. 4. When the edge is trimmed, stop sawing and remove the blade. Then, line up the new edge with the old one and saw through the middle.

Why Did You Trim Wood Edges?

There are many reasons why you might need to trim wood edges. The most common reason is to create a smooth, clean edge that will be easy to work with. This is especially important if you are working with finished wood or if you plan to stain or paint the piece. A jagged edge can be difficult to sand down and will often result in a poor finish. Another reason you might need to trim wood edges is to create a specific shape or design.

For example, you might need to create a curved edge or chamfer (beveled edge). A standard blade on a saw will not be able to create these types of edges. Finally, you might need to trim wood edges for safety reasons. If the edge is sharp or jagged, it could cause injury. Sometimes, you might need to trim wood edges to comply with safety regulations.

Things You Will Need

- A saw with a specialty trimming blade

- A work table or other flat surface

- Gloves (optional)

- Eye protection (optional)

Step by Step How to Trim Wood Edges

1. Set Up Your Work Area.

The first step is to set up your work area. You will need a saw with a specialty trimming blade and a work table or other flat surface. If you are working with a power saw, make sure it is unplugged before you begin. You should also wear gloves and eye protection if you have them.

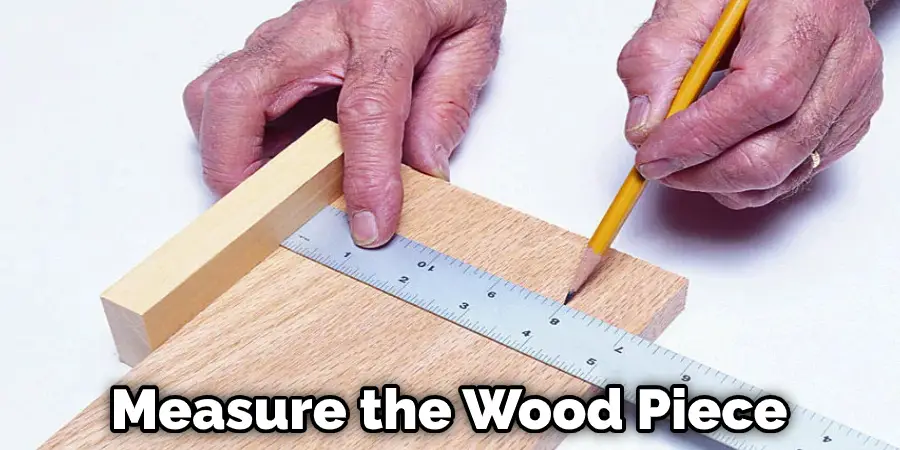

2. Measure the Wood Piece.

The next step is to measure the wood piece. You will need to know the width, height, and thickness of the piece in order to select the right blade for your saw. Wood is sold in different thicknesses, so be sure to measure carefully before making your purchase. If you are unsure of the thickness, ask a sales associate for help.

3. Select the Right Blade.

Once you have measured the wood piece, you can select the right blade for your saw. There are many different types of trimming blades available, so be sure to pick the one that is best suited for the material you’re working with. For example, if you’re trimming a piece of pine, you would want to use a blade with fewer teeth so that it can create a cleaner cut.

4. Mark the Cutting Line With a Pencil.

After you have selected the right blade, it’s time to mark the cutting line with a pencil. Make sure the line is straight, and use a level to make sure it’s level. If you’re not confident in making a straight line, you can use a chalk line or a laser level. If you’re using a power saw, you’ll also want to make sure the line is perpendicular to the wood grain.

5. Install the Trimming Blade.

Now it’s time to install the trimming blade. If you’re using a hand saw, this is a relatively easy process. Follow the manufacturer’s instructions for installing the blade. The process is a bit more complex if you’re using an electric trimmer. First, you’ll need to remove the guard from the trimmer. Next, use the Allen wrench to loosen the clamping screw and remove the old blade. Then, insert the new blade into the trimmer, ensuring that the teeth point in the right direction. Finally, use the Allen wrench to tighten the clamping screw.

6. Put on Gloves and Eye Protection (Optional).

If you haven’t already done so, now is the time to wear gloves and eye protection. These items are not required, but they will help to protect your hands and eyes from flying debris. If you have long hair, you may also want to tie it back to keep it out of your face.

7. Position the Wood Piece on the Work Surface.

Once you have installed the trimming blade, it’s time to position the wood piece on the work surface. If you’re using a hand saw, you’ll need to clamp the wood down so it doesn’t move while cutting. If you’re using a power saw, you can either clamp the wood down or use a guide to help you keep the blade in a straight line.

8. Start Cutting the Wood Edge.

Now it’s time to start cutting the wood edge. If you’re using a hand saw, you’ll need to apply gentle pressure as you move the saw back and forth. Using an electric saw, you can apply a little more pressure. Just be careful not to put too much pressure on the saw, or you could end up with a messy cut. As you’re cutting, keep the blade perpendicular to the wood. If the blade starts to tilt, you could end up crooked cut.

9. Stop the Saw.

Once you’ve reached the end of the cutting line, it’s time to stop the saw. If you’re using a hand or saw, release the pressure on the blade and allow it to come to a stop. If using an electric saw, release the trigger to stop the blade. Again, be sure to keep your fingers well away from the blade as it comes to a stop.

10. Remove the Blade.

After the blade has stopped, it’s time to remove it from the wood. Pull the blade out of the cut if you’re using a hand or saw. If you’re using a power saw, turn it off and unplug before removing the blade. With the blade removed, you can now finish the cut by hand.

11. Dispose of the Trimming Blade.

After finishing the cut, it’s time to dispose of the trimming blade. Be sure to follow the manufacturer’s instructions for disposing of the blade. If you’re not sure how to properly dispose of the blade, contact your local waste disposal company.

12. Sand the Edges.

Once you have trimmed the edges, you’ll need to sand them to smooth out the rough edges. You can use a hand sander or an electric sander for this. Start with coarse sandpaper and work your way up to a finer one. Wipe away the dust with a damp cloth after each sanding.

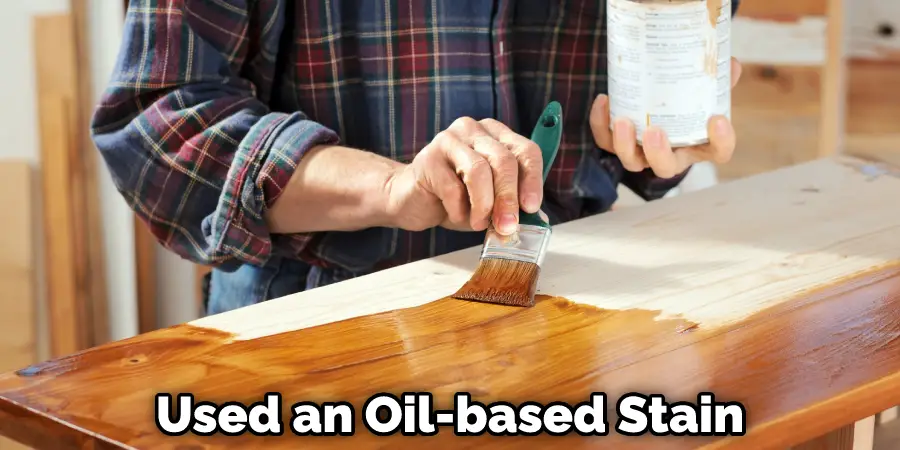

13. Stain or Paint the Wood Piece.

Once you have sanded the edges, you can now stain or paint the wood piece. If you’re staining the wood, be sure to use a pre-stain conditioner to help the stain adhere evenly. Once you have stained or painted the wood, you can now add a top coat to protect the finish. When choosing a top coat, be sure to choose one that is compatible with the stain or paint you used.

For example, if you used an oil-based stain, be sure to use an oil-based top coat. Next, apply the top coat according to the manufacturer’s instructions and allow it to dry completely. Once the top coat has dried, you can add any hardware to the piece—screws, nails, hinges, etc.

14. Enjoy Your Newly Trimmed Wood Edges.

You’ve now successfully trimmed the edges of your wood piece. Enjoy your newly trimmed wood, and be sure to show it off to your friends and family. If you need to trim wood edges again, be sure to refer back to this guide.

Tips and Warnings on How to Trim Wood Edges:

Tips:

- Pick the right tools. For a basic wood edge, you won’t need anything too fancy–just a sharp hand saw and a miter box will do the trick. But if you’re working with a more delicate or intricate piece, you may want to consider investing in power tools like an electric hand sander or jigsaw.

- Measure twice, cut once. Before you start cutting, taking accurate measurements of the piece you’re working on is important. Otherwise, you risk ending up with pieces that are too small or too big.

- Test your cuts on scrap wood first. If you’re unsure about how to make a particular cut, it’s always a good idea to practice on a piece of scrap wood first. That way, you can get a feel for the cut before committing to it on your final piece.

- Use clamps to secure the workpiece. This will help to prevent the piece from moving around while you’re working on it and will also help to protect your hands from getting too close to the blade.

- Be careful with the blade. Always ensure that your saw’s blade is pointing away from you when you’re cutting, and be extra careful when making curved or intricate cuts.

Warnings:

- Wear safety goggles to protect your eyes from flying debris.

- Use gloves to protect your hands from the blade.

- Be sure to unplug power tools before changing blades or making any adjustments.

- Never force a cut–if the blade is having trouble cutting through the wood, try repositioning the piece or using a different blade.

- Be aware of your surroundings–make sure that there’s nothing in the way that could get caught on the blade or interfere with your cut.

Which Edge Banding is Best?

Edge banding covers the exposed sides of the plywood, MDF, or particleboard to give it a more finished look. There are several types of edge banding available in the market, such as PVC, ABS, Veneer, and Wood. Each edge banding type has unique properties, advantages, and disadvantages.

PVC edge banding is a very popular option in the furniture industry as it provides a durable and cost-effective solution. It is made of plastic and can be easily molded to fit the edges of the board. However, it is not as environmentally friendly as other options and can release harmful chemicals during production.

ABS edge banding is another popular choice. It is made of thermoplastic materials and is known to be very impact-resistant. ABS edge banding is also recyclable and more environmentally friendly than PVC. However, it is slightly more expensive than PVC and can be more difficult to apply.

Veneer edge banding is a thin layer of real wood that is applied to the edges of the board. It provides a beautiful finished look that is very natural and authentic. However, veneer edge banding can be costly and not as durable as some other options.

What is the Edging Process in Wood?

The edging process in woodworking is a fundamental procedure in creating a wooden board or panel. This process involves cutting the rough wood plank into smaller pieces, glued along their long edges to form a wider, more stable panel.

This procedure minimizes the effects of wood movement that naturally occurs in certain conditions, such as humidity changes. Edging the wood into boards improves the durability of the wood since the wooden pieces expand and contract in the same way, reducing the risk of cracking or splitting.

The edging process can be accomplished using either a jointer or a table saw. A jointer’s edges are straightened and smoothed out, ensuring precise gluing points. When using a table saw, the edges are stripped of bark and smoothed out to achieve parallel edges.

After the edging process, the wood pieces are glued together to form a larger panel. This process may take some time since the glue must be carefully applied, and pressure must be maintained while the glue dries. When the glue is completely dry, the panel is sanded to eliminate any rough spots, and the edges are trimmed back.

Conclusion

This article has shown you how to trim wood edges. It is important to use the correct tools and take your time when performing this task. With a little practice, you will be able to achieve professional results. Thanks for reading.