Are you looking to create something unique and eye-catching? If so, sublimation on wood may be the perfect project for you. Sublimating on wood allows you to transfer images, designs, or text onto various materials in vivid color and detail – giving your project depth that simply isn’t achievable with other printing methods. With the right setup and supplies, anyone can learn how to sublimate on wood with success.

Whether you are creating custom signage, awards, or personalized gifts, sublimating on wood is a great way to make an impression. Always start by ensuring your wood is free of dust, dirt, or other residue before the sublimation process begins.

In this blog post, we will outline instructions on sublimating on wood, along with helpful tips and tricks from industry professionals so that you can start bringing your vision alive!

What are the Advantages of Sublimating on Wood?

When you learn to sublimate on wood, you create something truly one-of-a-kind. The vibrant colors and detail from the sublimation process bring your projects to life. Additionally, some people prefer wood for its environmental advantages over metals or plastics.

Another advantage of using wood is that it can offer more flexibility in shape and design. Many products come pre-cut, but you also have the freedom to cut out custom shapes for specific projects.

Overall, learning how you can sublimate on wood provides you with a unique tool for creating eye-catching and custom products.

What Will You Need?

Before you begin the sublimation process, make sure to have all the necessary supplies on hand. You will need:

- Heat press

- Sublimation paper

- Sublimation ink

- Protective cover sheet

- Plain wood surface or substrate

- Masking tape (optional)

Once you have gathered all these items, it’s time to start!

10 Easy Steps on How to Sublimate on Wood

Step 1. Use Wood Surface:

Start by using a plain wood surface or substrate. Do not use painted, treated, or varnished wood; it will not accept the sublimated image. If still determining if the wood is suitable, try a test patch first.

Step 2. Sand Surface:

Using fine-grit sandpaper, lightly sand the surface of the wood to create a smooth finish and prepare it for sublimation. Remove any dust or debris from the wood surface before continuing. Try to avoid creating any deep scratches or gouges during this step.

Step 3. Place Image on Wood:

Print your desired image onto sublimation paper using sublimation ink. Cut out the image so that it fits your substrate and place it face down onto the wood. If needed, use masking tape to secure the image in place on top of the wood surface.

Step 4: Preheat Press:

Set up your heat press machine according to the manufacturer’s instructions. Preheat the press to 400°F (200°C). Use the highest setting available if your heat press does not have a temperature setting.

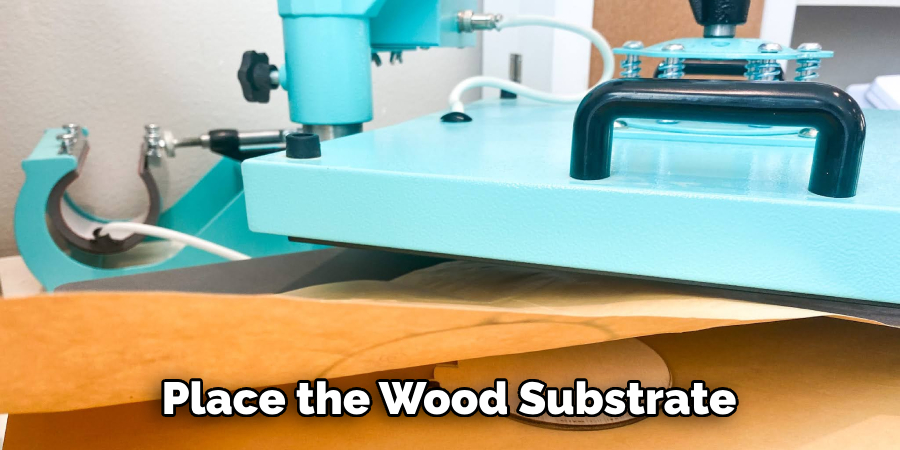

Step 5: Place Wood in Press.

When preheating is complete, place the wood substrate with the image face down on the bottom plate of the heat press. Close and lock the press for a few seconds, then open it again to ensure the image is evenly pressed onto the wood surface. If not, reposition and close again.

Step 6: Cover Image with Protective Cover Sheet:

Place a protective cover sheet over your image, ensuring it covers the entire design completely. This will help protect against any burning or scorching when applying heat. The cover sheet will also help reduce any chances of ink smearing or shifting.

Step 7: Press Wood into Heat Press Machine :

Carefully close and lock the press. Set the timer for 2 minutes and press at medium-to-high pressure. If needed, adjust the pressure accordingly.

Step 8: Release Heat Press :

When the time is up, release the heat from your press and carefully remove the wood substrate with an image. You can use a soft cloth or towel to help protect the wood surface from accidental burns. Another option is to use an oven mitt or hot pad.

Step 9: Remove Paper From Wood :

Once your piece has cooled, gently peel away the sublimation paper from the wood surface to reveal your newly transferred image! Remember that the image may appear slightly different from what you printed due to sublimation ink’s natural reaction with heat. Another tip: be sure to move quickly and efficiently during this step, as the paper can still easily tear while it is warm.

Step 10: Enjoy Your Sublimated Wood Piece :

Congrats – you have just learned to sublimate on wood! Now it’s time to enjoy your beautiful finished product. Whether you are creating something for yourself or a gift, sublimation on wood is sure to make an impression.

By following these ten steps, you will have a successful project in no time! With the right supplies and instructions, anyone can master sublimating on wood.

5 Additional Tips and Tricks

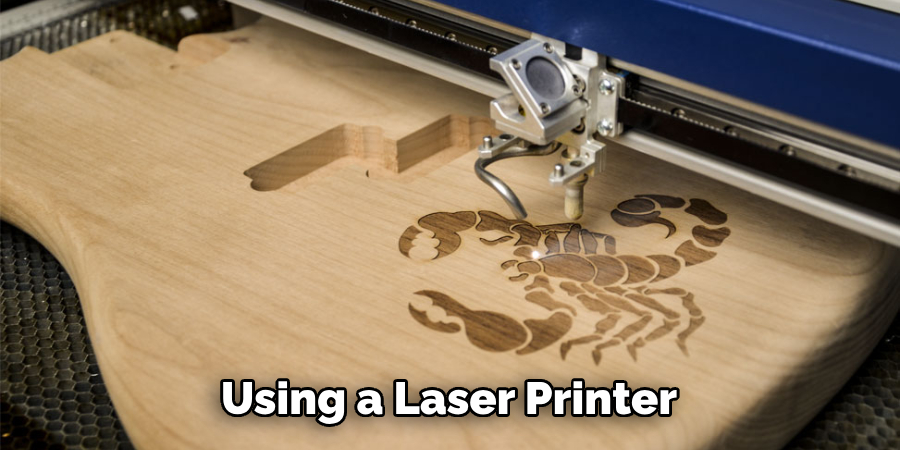

1. If you are using a laser printer, ensure the ink is not water soluble, or it will not transfer correctly.

2. Before sublimation, sand and sand your wood to create a smooth surface for better ink adhesion.

3. When pressing the image onto the wood, use an even pressure so the entire design transfers properly.

4. High heat settings can cause warping or burning of your wood piece, so be sure to adjust accordingly and keep track of the time and temperature on each item you press.

5. A silicone mat between your wood and iron helps protect against any unwanted scorching or staining of your workpiece – just remember to change out mats after several uses. Using a Teflon cloth between your wood and iron will also help keep your workpiece clean and free from damage.

Following these tips should help ensure that you get the best results when sublimating on wood! You’ll be creating beautiful pieces with practice and patience in no time.

5 Things You Should Avoid

1. Do not use any wood surface that has already been painted or treated with varnish. The image will not transfer properly, and it may cause damage to the wood surface.

2. Do not allow the heat press to remain closed for too long or at too high of a temperature, as this can cause burning or warping of the wood surface.

3. Avoid using water-soluble ink when printing your image onto sublimation paper, as it will not transfer correctly.

4. Make sure to use even pressure when pressing your image onto wood, otherwise, parts of the design may be lost or shifted during the process.

5. Never place any type of adhesive onto your wood before attempting to sublimate, as this will interfere with the process and result in fading or discoloration of the image over time.

By following these simple tips and avoiding these common mistakes, you can ensure that your wood pieces turn out perfectly.

Can You Sublimate Directly Onto Wood?

No, you cannot sublimate directly onto wood. The sublimation process requires a special type of paper and ink incompatible with the wood’s surface.

To achieve a successful result, you must first print your image onto sublimation paper using sublimation ink and then place it on top of the wood surface for pressing. If you try to skip this step, the image will not transfer properly and may cause damage or discoloration to the wood.

Sublimating on wood can produce beautiful results when done properly, so make sure to follow all instructions closely to get the best outcome possible!

Why is Your Sublimation Not Bright?

If your sublimated image is less bright and vibrant than you would like, it could be due to a few factors. Firstly, it may be caused by using low-quality or expired sublimation ink. Make sure that the ink you are using is fresh and of good quality to get the best results possible.

Another common cause of dullness is if your heat press settings need to be higher or the timer is set for too short of a duration. The temperature must be set at 400°F (200°C) and remain constant throughout the pressing process. Additionally, the press should stay closed for at least 2 minutes or more for optimal saturation levels.

If all else fails, try switching to a different brand of sublimation paper, as some types may be better suited for achieving brighter colors than others. Following all instructions closely and using high-quality supplies should help ensure that your sublimated image turns out just right!

What Type of Heat Transfer is Wood?

Wood is considered a “sublimation” type of heat transfer. This means that a special type of ink and paper must be used, as regular inkjet printers can not produce this effect. Sublimation inks transform into gas when heat is applied to the substrate (wood). This gas penetrates deep into the wood surface and leaves behind lasting vibrant colors with superior resolution and detail.

Additionally, sublimation requires a higher temperature setting than other types of heat transfer, usually around 400°F (200°C).

Overall, sublimating on wood is a more difficult process than other methods of heat transfer due to the specialized supplies and tools required. However, with the right instructions and supplies, anyone can create beautiful pieces with this technique!

Conclusion

Sublimating on wood can be a creative way to make custom gifts that stand out. Gifting an item with a personalized touch shows the recipient how special they are and allows them a meaningful keepsake that will last.

Whatever the occasion, sublimating wood is an innovative technique combining the natural beauty of wood grain with personalized graphics and text. Sublimation is growing in popularity, and now more than ever, there are plenty of fun ways to jazz up your wood items!

Whether trying to find something for yourself or someone else, explore the possibilities of creating exciting yet unique handmade gifts with sublimation printing. With some creativity and practice, you’ll soon discover how easy it is to customize wood items in no time!

Hopefully, the article on how to sublimate on wood has helped guide you through the process. It’s time to take on your project and use this newfound knowledge to create something extraordinary! Good luck!