Plywood is a multi-layered wood material made from thin sheets of wood called veneers. The edges of the plywood are often left unsanded and unfinished, which can cause the wood to become exposed to moisture and water damage over time. Sealing the edges of plywood helps protect it from environmental elements and prevents it from warping or rotting. It also adds a decorative touch to the project, making it look more polished and professional.

The primary advantage of sealing the edges of plywood is that it helps protect and extend the life of the wood. Sealing the edges prevents moisture from entering and damaging the boards, which can lead to warping or rotting.

It also creates an airtight seal that keeps out dust, insects, or other debris that could otherwise get trapped in the plywood. This can help maintain a cleaner surface, which is important for any project. In this blog post, You will learn in detail how to seal the edges of plywood.

What Methods Are Available for Sealing the Edges of Plywood?

Sealing the edges of plywood is an important step for ensuring that your projects remain weatherproof and durable. There are several methods available for sealing the edges, depending on the needs and nature of your project. One of the most common ways to seal plywood edges is with a polyurethane or varnish sealant. Polyurethane and varnish both form a protective layer over the edge of the plywood while also providing aesthetic value.

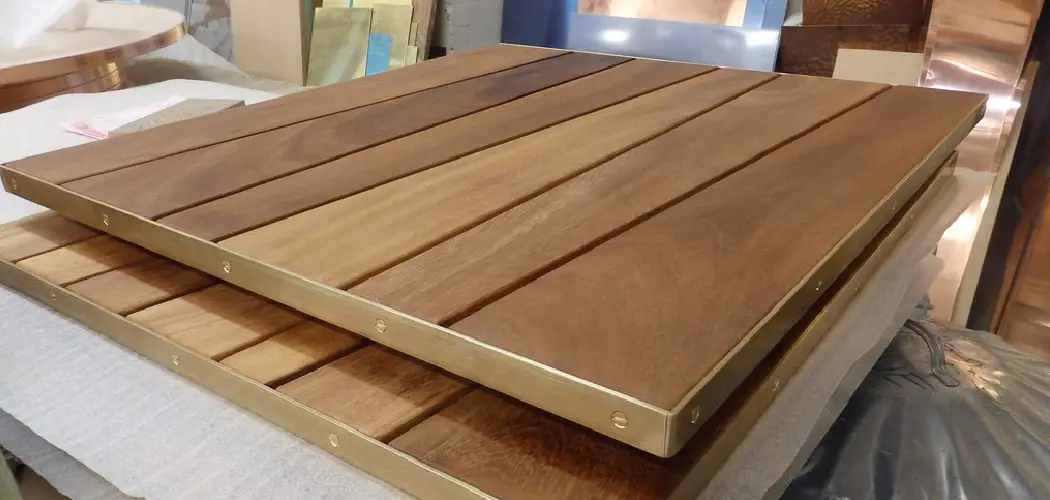

This method is ideal for projects that are intended to be seen, such as furniture or cabinets. The sealant can be applied with a paintbrush or roller and should be given sufficient time to dry before use. For projects that are not intended to be seen, a less time-consuming and cost-effective method is to use an edge banding trim.

Edge banding trim is available in a variety of different materials, such as PVC or wood veneers, and can be applied using an iron or hot air gun. This method creates a durable seal along the edges of the plywood while also providing an attractive finish.

Tools You Will Need

- Sandpaper

- Paintbrush

- Wood sealer

- Wood glue

- Knife or saw

- Masking tape

- Exterior grade plywood

- Caulk gun

- Putty knife

- Hammer and nails (optional)

Step-by-step Instructions for How to Seal the Edges of Plywood

Step 1: Inspect the Plywood

Before attempting to seal the edges of the plywood, you should inspect it for any signs of damage. Look for cracks, splinters, and other irregularities that could cause the sealant not to adhere properly.

Step 2: Sand the Edges

Once you have inspected the plywood, use a sandpaper to smooth out any rough or jagged edges. This will help ensure that the sealant adheres to the surface properly. Use a damp cloth to remove any dust or debris from the edges of the plywood. Make sure the surface is dry before moving on to the next step.

Step 3: Apply Sealant

Apply an even layer of sealant to the edges of the plywood. Make sure to cover all areas, including any cracks or crevices. Allow the sealant to dry completely before moving on to the next step. Depending upon the type of sealant used, this could take up to 24 hours.

Step 4: Apply Primer

Use a paintbrush to apply a primer to the edges of the plywood. This will help protect the sealant and ensure it lasts longer. Allow the primer to dry completely before moving on to the next step. Depending on the primer type, this could take up to 24 hours.

Step 5: Paint the Edges

Use a paintbrush to cover the edges of the plywood with a coat of paint. Ensure all areas are covered, and there are no missed spots. Allow the paint to dry completely before moving on to the next step. Depending upon the type of paint used, this could take up to 24 hours.

Step 6: Apply Clear Coat

Use a paintbrush to apply a clear coat over the painted edges of the plywood. This will help seal the color and protect it from wear and tear. Allow the clear coat to dry completely before using the plywood.

Following these steps will help ensure that the edges of the plywood are properly sealed and protected from damage. Be sure to follow all instructions closely and use proper safety protocols when working with sealants, primers, and paints.

Safety Tips for How to Seal the Edges of Plywood

- Wear safety goggles, gloves, and a dust mask when handling plywood.

- If you are sanding the edges of the plywood, use an electric sander to reduce the potential inhalation of wood particles.

- Ensure your work area has adequate ventilation, so fumes do not accumulate.

- Be careful with the application of sealants and adhesives. Follow all manufacturer’s instructions and safety recommendations.

- If necessary, wear a respirator when applying wood glue or adhesive to ensure you don’t inhale any vapors.

- Use appropriate safety equipment for any painting or staining that may be required for sealing the edges of the plywood.

- Make sure to clean up any spills or residue in your work area immediately to avoid potential hazards.

- Store all paints, solvents, and sealants in a secure location away from children and pets when not in use.

Following these safety tips will help ensure you can properly seal the edges of plywood without any unnecessary risks. With some careful preparation, you can ensure a safe and successful project.

Is There a Way to Test if the Edges of the Plywood Have Been Properly Sealed?

Yes, there is a way to test if the edges of the plywood have been properly sealed. Once the sealant has been applied and dried, you can perform a simple water test to make sure that it is adequately waterproofed. To do this, simply apply some water to the edge of the plywood with a spray bottle or paper towel. If the edge absorbs some of the water, it is not adequately sealed, and you should use additional sealant to ensure that the edges are waterproofed.

Additionally, you can also apply a bead of caulk along the edges of the plywood before sealing them. This will provide an extra layer of protection against moisture and help ensure that the plywood edges are completely waterproof. Once the caulk has been applied and dried, you can apply a sealant to seal up any gaps or cracks along the edge of the board. Finally, if you do not feel confident in properly sealing the plywood edges, it is always best to hire a professional contractor.

Is There Any Special Maintenance Required for Sealed Plywood Edges?

Once the edges of your plywood have been sealed, some regular maintenance may be necessary to ensure they stay in good condition. Regularly inspect the edges and ensure no cracks, chips, or other damage could compromise the sealant layer.

If any damage is noticed, apply a new coat of sealant over it to keep it watertight. Even if you don’t notice any damage, reapplying the sealant every few years is recommended to ensure the edges are properly protected from moisture and other environmental factors.

The application process for resealing is the same as when first sealing them – use a brush or roller to apply an even layer of waterproof sealant and let it dry before subjecting the plywood to moisture or regular use.

Doing this will help keep your plywood edges in good condition for many years so they remain watertight and undamaged. By taking these steps, you can ensure that your plywood is always properly sealed and ready to withstand whatever use you need it to.

How Long Will It Take for a Sealant to Cure on the Edges of Plywood Fully?

The time it takes for a sealant to cure on plywood edges depends largely on the type and brand of sealant used. Generally speaking, most sealants take around 24 hours to cure completely. Certain brands may take up to 48 hours to fully set, while others can be ready in as little as 12-16 hours.

To ensure the sealant cures properly, it is best to follow directions on the packaging of your particular product and allow additional time for proper curing if necessary. Additionally, some sealants may require a few coats or multiple applications depending on the desired outcome, which could also affect how long it takes for a sealant to cure fully.

For best results, it is always recommended to use a quality sealant specifically designed for use on plywood. Always read and follow the instructions carefully to ensure proper application and curing of the sealant. This will help create a durable and long-lasting seal that protects your plywood edges from moisture, rot, and other contaminants.

Are There Any Special Techniques Used When Sealing the Edges of Curved Pieces of Plywood?

When sealing the edges of curved pieces of plywood, there are certain steps to take in order to ensure that the wood is properly sealed. The first step is to carefully sand down any rough edges or imperfections in order to create an even surface on which the sealant can be applied. Once all of the surfaces have been sanded, it is important to clean the entire surface of dust and debris with a damp cloth.

The next step is to apply the sealant. When applying the sealant to curved pieces of plywood, it is important to use a brush or roller that will follow the contours of the wood without leaving any gaps or lines in between.

If needed, small pieces of tape may be used to help keep the sealant in place. Once the sealant has been applied and dried, it is recommended that a few coats of paint or varnish are applied further to protect the wood from moisture and other elements.

Are There Any Environmental Considerations When Sealing the Edges of Plywood?

Yes, there are several important environmental considerations to keep in mind when sealing the edges of the plywood. Plywood is a composite material made from thin layers of wood veneer glued and pressed with an adhesive.

Sealants used on plywood edges should be non-toxic, low VOC (volatile organic compound), and safe for indoor and outdoor applications. Choose a sealant that is certified by an independent, third-party laboratory to meet the standards of Green Seal or similar certification programs.

Additionally, it’s important to select a sealant with a low odor so as not to cause any health problems in your home or environment. Finally, use a sealant that is designed to resist mold and mildew, which can be caused by moisture seeping into unsealed wood. By considering these environmental considerations, you can ensure that your plywood edges are properly sealed without harming the environment.

Conclusion

One of the main disadvantages of using a sealant when sealing the edges of plywood is that it is not always as durable as other methods. Sealants can be scraped or rubbed off over time, making them much less effective in protecting your project from moisture and other types of damage. If you choose to use a sealant, be sure to reapply it every few months or so to ensure maximum protection.

In conclusion, sealing the edges of plywood is an important step in finishing any project. It can help keep moisture out, prevent splintering, and give your wood a finished look. There are many ways to do this, from using sealants and gels to painting or staining the edges.

Each method will provide different levels of protection, so it’s important to consider which option will work best for the project you’re working on. Additionally, it’s important to take the necessary safety precautions when using sealants and gels to avoid any potential problems. I hope reading this post has helped you learn how to seal the edges of plywood. Make sure the safety precautions are carried out in the order listed.