If you are a professional or hobbyist woodworker, you know the importance of having a good band saw blade. A quality blade will make ripping and crosscutting much smoother and more accurate. Measuring a band saw blade can seem daunting, but with the right techniques, it’s a breeze.

This blog post will show you how to measure band saw blades to ensure you are getting the right fit. We will also recommend some of our favorite blades for different woodworking projects. Let’s get started!

Summary: If you’re looking to buy a band saw blade, the first thing you’ll need to do is measure your saw’s table. This is easy to do, but there are a few things you need to keep in mind. The measurement you take will depend on the size of your saw’s table and the type of blade you’re using. To measure your table, use a straight edge to draw a line across the top of the blade at the same height as your saw’s table. Then, use a ruler to measure the distance between the line and the edge of the blade. This number is the blade’s width in inches. To measure the blade’s length, draw a line along the top of the blade at the same height as your saw’s table. Then, measure the distance between the line and the edge of the blade.

What Tools & Supplies You’ll Need?

To measure a band saw blade, you will need the following tools and supplies:

- A tape measure

- A band saw

- A band saw blade

- A piece of wood

Step by Step Instructions: How to Measure Band Saw Blades

Step 1: Determine the Width of Your Band Saw Blade.

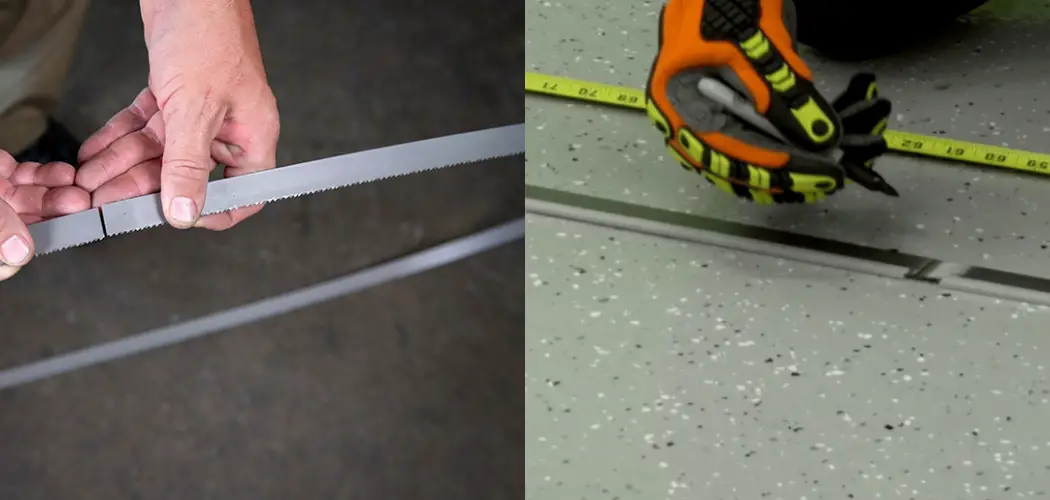

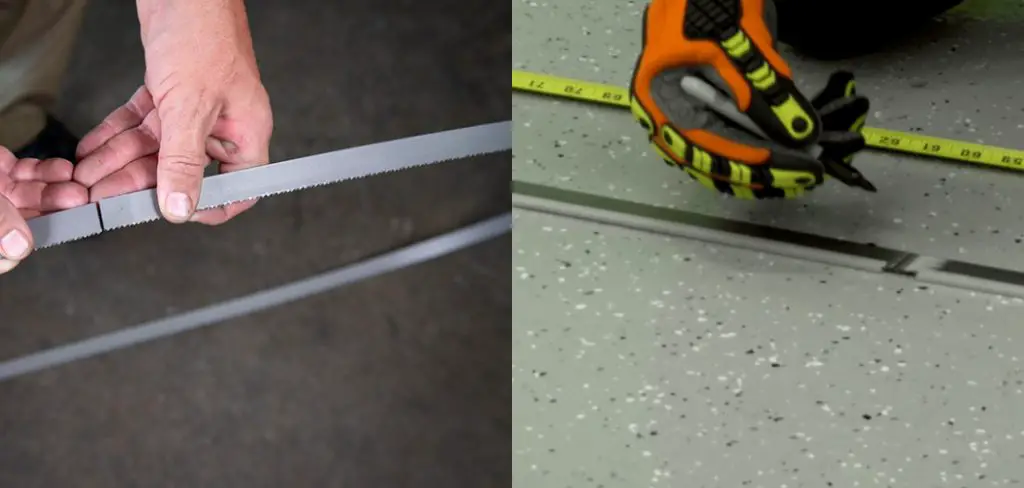

The first thing you need to do is determine the width of your band saw blade. Next, you can measure the inside of the band saw’s throat. To get an accurate measurement, use a tape measure and measure from the tip of one blade tooth to the tip of the blade tooth on the other side.

Step 2: Determine the Thickness.

Now that you know the width of your band saw blade, you need to determine the thickness. The thickness is determined by measuring the blade’s kerf, or cutting width. To measure the kerf, simply place the blade on a flat surface and measure the width of the cut.

Step 3: Measure The Depth of Your Band Saw’s Blade.

The depth of your band saw’s blade is important to know to get the correct length of the blade. To measure the depth, place the blade on a flat surface and measure from the top of the blade to the bottom. Be sure to measure the entire blade, including the teeth. When the blade is installed on the saw, the teeth should protrude from the blade’s bottom.

Step 4: Measure the Center-to-center Distance.

The center-to-center distance is the distance between the centers of the two blade wheels on your band saw. You will need to remove the blade from the saw to measure this. Once the blade is removed, measure from the center of one wheel to the center of the other wheel. Make sure the blade is completely removed from the saw before taking this measurement.

Step 5: Determine the Type of Blade You Need.

Now that you know all of the measurements, you can determine which type of band saw blade you need. The three main types of band saw blades are regular, hook tooth, and skip tooth. Regular blades have teeth that are all the same size and shape. These are the most common type of blade and can be used for various materials.

Hook tooth blades have teeth that are larger in the center and taper down to smaller teeth at the edges. These blades are good for cutting curved or irregular shapes. Skip tooth blades have teeth spaced further apart than regular or hook tooth blades. These blades are good for making quick, rough cuts.

Step 6: Add One Full Wheel Circumference.

Once you have determined the type of blade you need, the next step is to add one full wheel circumference to your measurement. This is important because it ensures that the blade will be long enough to wrap around the entire wheel. To get the circumference of the band saw’s wheels, measure the distance around the outside edge of one of the wheels.

Now that you know how to measure band saw blades, you can be sure to get the right blade for your next project. Be sure to check out the different selection of band saw blades to find the perfect one for your needs.

Additional Tips and Advice

- Always wear safety glasses when working with power tools.

- Use a piece of wood to protect your fingers when measuring the blade’s kerf.

- When removing the blade from the saw, be careful not to touch the sharp teeth.

- Be sure to add one full wheel circumference to your measurement to ensure that the blade will fit around the entire wheel.

- If you are unsure of the size blade you need, consult your band saw’s owner’s manual or contact the manufacturer.

- Make sure the blade you select is the correct type for the material you will be cutting.

- If you don’t have a tape measure, you can use a ruler or a piece of string to measure the blade. Just be sure to mark the spot on the blade where you start and stop your measurement.

- Always follow the manufacturer’s recommendations for installing and using band saw blades.

What to Look For When Choosing a Band Saw Blades?

There are a few things you should keep in mind when choosing a band saw blade. Here we have compiled a list of the most important factors:

1. Tooth Profile:

The tooth profile is the shape of the teeth on the blade. It is important to choose a blade with the right tooth profile for the material you will be cutting. When choosing a tooth profile, ensure that the gullet is deep enough to clear the chips and that the teeth are sharp enough to cut through the material.

You Can Check It Out to Measure Wood for a Bevel Cut

2. Cutting Direction:

The cutting direction refers to the direction in which the blade cuts through the material. For example, some blades are designed for rip cuts, while others are designed for cross cuts. Make sure you choose a blade designed for the type of cut you will be making. If you choose a blade not designed for the type of cut you will be making, the blade will not cut as efficiently and may even damage the material.

3. The Kerf of the Blade:

The kerf of the blade is the width of the cut that the blade makes. The wider the kerf, the more material is removed with each cut. A wider kerf is good for thick materials but will also remove more material from thinner materials. Choose a blade with a kerf that is appropriate for the thickness of the material you will be cutting.

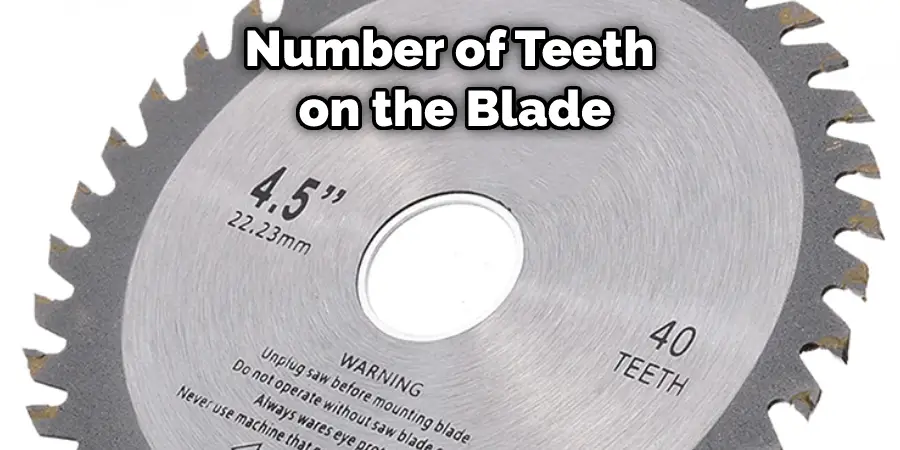

4. The Number of Teeth on the Blade:

The number of teeth on the blade determines how fast the blade will cut through the material. A blade with more teeth will make a smoother cut, but it will also take longer to cut through the material. Choose a blade with the right number of teeth for the type of material you will be cutting and the speed at which you want to cut.

5. The Type of Material you will be Cutting:

The type of material you will be cutting will determine the type of blade you need. Some materials, such as aluminum, require a different blade type than others, such as wood. Make sure you choose a blade designed for the type of material you will be cutting.

You Can Check It Out To Tight Should a Bandsaw Blade Be

How to Fix a Band Saw Blades That’s Missing Teeth?

If your band saw blade is missing teeth, there are a few things you can do to fix it. First, try to determine the cause of the problem. If the blade was damaged, you might be able to repair it with a file. If the problem is due to wear, you may need to replace the blade. Finally, if the problem is due to damage, you will need to remove the damaged portion of the blade.

First, disconnect the band saw from its power source. Then, use a file to remove any burrs or sharp edges from the blade. Next, use a grinding wheel to remove any damaged teeth. You will need to replace the blade if the problem is due to wear. First, disconnect the band saw from its power source.

Then, remove the old blade from the saw. Be careful not to damage the teeth on the new blade. Next, install the new blade and reconnect the band saw to its power source. Finally, test the new blade by running it through a piece of wood. If the blade is still not working properly, you may need to adjust the tension on the saw.

How to Select a Blade?

Selecting the right band saw blade for the job is an important step toward achieving a successful cut. A band saw blade is composed of two main components – the teeth and the backing material. The number, shape, and set of the teeth on a particular blade can greatly affect how well it performs its task. When selecting a blade, it is important to consider the type of material you are working with and what shape you want the cut to be.

The first step in using a jointer planer is to measure the width and depth of your workpiece. The size of these measurements will determine the type and size of the blade that you need. The standard widths for a planer blade are 1/4 inch, 3/8 inch, and 1/2 inch. The cut’s depth will determine the thickness of the blade you need – thicker blades provide more support to prevent vibration when cutting hard materials such as wood or metal.

Final Words

Measurement of band saw blades is an important step in the manufacturing process. By taking accurate measurements, you can ensure that your blades are cut to the correct size and specifications. There are a few different ways to measure band saw blades, each with its benefits and drawbacks.

In this blog post, we have discussed the most common methods for blade measurement. We have also provided tips on getting the most accurate measurements possible. We hope this guide on how to measure band saw blades has been helpful. If you have any questions or want to know more, feel free to comment below!