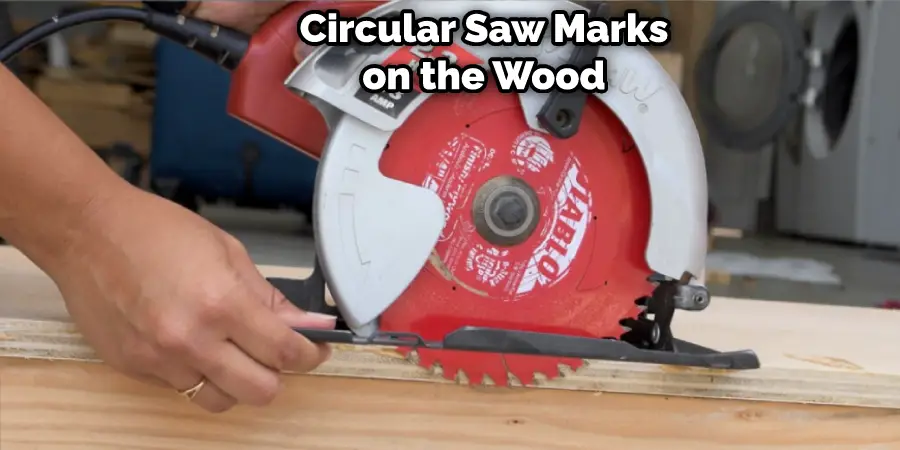

Circular saw marks can be fascinating to look at and are a great way to add some visual interest to your woodworking projects. In this post, we’ll show you how to make circular saw marks on wood quickly and easily. So let’s get started!

Summary: Making saw marks on wood is easy with a circular saw. First, find the center of the board and make a mark with a pencil. Next, position the blade of the saw near the mark and make a small cut. The saw will start to move around the circumference of the board, making the desired saw mark.

What Are Circular Saw Marks on Wood?

If you’ve ever looked at a piece of lumber and noticed saw marks going in a circle around the edges, you may have wondered what they are. These marks are called “circular saw marks,” and they’re made by a type of saw that’s specifically designed for cutting curves.

While a straight-edged saw is great for making long, straight cuts, it’s not so good at cutting curves. That’s where a circular saw comes in. By rotating the blade in a circle, a circular saw can easily follow even the most complicated curves.

As a result, it’s the ideal tool for cutting trim and molding. So the next time you see circular saw marks on a piece of wood, you’ll know that it was cut with precision and care.

Why Should You Make Circular Saw Marks on Wood?

Whenever you need to cut wood, you should always use a circular saw. Not only does this type of saw allow for more precise cuts, but it also leaves behind telltale marks that can be helpful in the future. The most important reason for making circular saw marks on wood is that it helps to identify the wood grain.

By looking at the direction of the markings, you can quickly determine which way the grain runs. This is helpful when making rip cuts, as you want to ensure that your blade moves against the grain. In addition, circular saw marks can also help you line up future cuts. By making reference points on either side of your initial cut, you can ensure that subsequent cuts are perfectly straight.

As a result, taking the time to make circular saw marks on wood can save you a lot of time and effort in the long run.

How to Make Circular Saw Marks on Wood Step-by-Step Guide

If you’re looking to add a unique touch to your woodworking projects, you may want to try making circular saw marks on your wood. While it may seem like a daunting task, it’s actually quite easy to do with the right tools and techniques. Here’s how you can make beautiful, intricate circular saw marks on wood:

1. Choose the Right Saw Blade

The first step to making perfect, clean cuts with your circular saw is to ensure that you are using the right saw blade for the job. If you are cutting through softwoods, such as pine or cedar, then you will want to use a blade with fewer teeth. You will want to use a blade with more teeth for hardwoods, such as oak or maple.

2. Set the Saw Blade Depth

The depth of your saw blade will determine how deep your circular saw marks will be. To set the blade depth, loosen the depth adjustment knob on your saw and lower the blade until it’s at the desired depth. Then, tighten the knob to lock the blade in place.

3. Adjust the Saw Blade Angle

The angle of your saw blade will determine the width of your circular saw marks. For example, a 45-degree angle will produce wider marks than a more shallow angle.

To adjust the angle of your saw blade, loosen the bolt that secures the blade in place. Then, rotate the blade to the desired angle. Once you have the blade at the correct angle, tighten the bolt to secure it in place.

4. Mark Your Cutting Line

Once you’ve chosen the right saw blade and set the depth and angle of your cut, you’re ready to start making some sawdust! But before you do, you need to take a few moments to mark your cutting line.

This is especially important if you’re working with expensive lumber or doing any type of precision work. A well-marked cutting line will help you make cleaner, more accurate cuts.

5. Cut Along the Cutting Line

Now it’s time to cut along your marked line. First, place the circular saw blade on the wood and align it with the cutting line. Then, apply gentle pressure to the saw and allow the blade to cut through the wood. Be sure to keep your hand steady as you cut to ensure a clean, straight line.

If you’re not experienced with using a circular saw, practice on a piece of scrap wood before cutting your project piece. This will help you get a feel for how to use the saw and avoid any accidents.

6. Finish the Cut

Once you’ve reached the end of your cutting line, slowly raise the saw blade out of the wood. Be sure to keep the blade perpendicular to the work surface as you finish the cut. If you need to make a second cut along the same line, simply position the saw blade at the beginning of the cutting line and repeat the steps above.

7. Repeat as Necessary

If you want to create multiple circular saw marks on your piece of wood, simply rotate the wood and make another pass with the saw. Remember to keep your hand placement steady and use a consistent speed as you work. With a little practice, you’ll be able to create perfect circular saw marks every time!

That’s it! You’ve now learned how to make circular saw marks on wood. With the right tools and techniques, it’s easy to add a unique touch to your woodworking projects. So go ahead and try it – your next project will be all the more impressive!

How Do You Make Saw Marks on Wood?

If you want to create saw marks on wood to achieve a rustic look or to simulate the work of hand tools, you can use a few different techniques. Here are some of the methods you can try:

- Hand-sawing: One of the most authentic ways to create saw marks is to use a hand saw. You can use a rip saw to make long cuts in the direction of the wood grain or a crosscut saw to make shorter cuts across the grain. Both types of saws will leave distinctive marks on the wood that can add character and texture. Use a saw with a coarse blade for best results, and work slowly and deliberately.

- Circular saw: If you have access to a circular saw, you can use it to create saw marks that are similar to those made by a hand saw. Use a rough-cut blade with many teeth to make the cuts, and be sure to adjust the depth of the blade so it doesn’t cut all the way through the wood. Move the saw back and forth over the wood to create a rough, textured surface.

- Chainsaw: A chainsaw can be used to create interesting saw marks for larger pieces of wood or logs. Use a chainsaw with a dull chain to create deep and rough cuts. Start by making shallow cuts in a random pattern, then go over them again to make them deeper and more pronounced. Be sure to wear appropriate protective gear, as chainsaws can be dangerous.

- Handheld sanders: If you want to create a more uniform or subtle saw mark pattern, you can use a handheld sander to do so. Attach a rough sanding disc or belt to the sander, and move it along the surface of the wood in a random pattern. This will create a texture resembling saw marks, even more than those created by hand or power tools.

Overall, the method you choose will depend on your desired look, the tools you have available, and your skill level. Regardless of which method you choose, take your time and work carefully to get the best results.

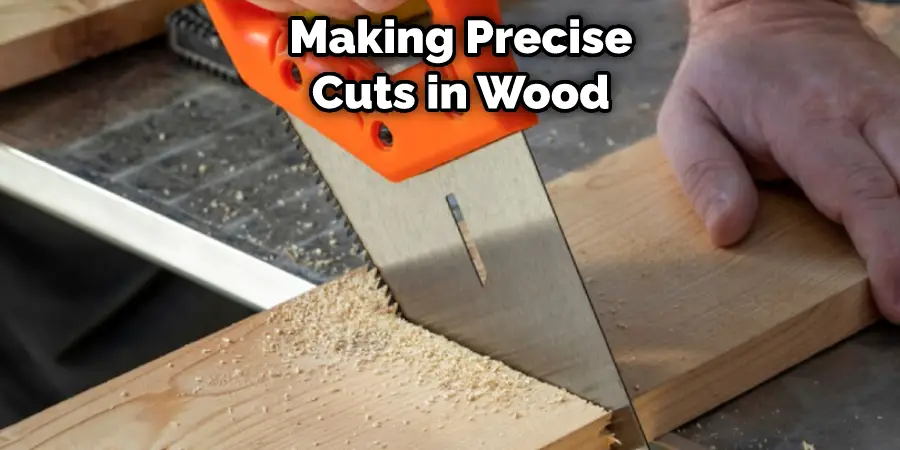

What Are the Best Blades for Making Circular Saw Marks on Wood?

When it comes to making precise cuts in wood, few tools are as versatile as a circular saw. Whether you’re trimming lumber for a deck project or cutting plywood for new cabinets, a circular saw can handle the job quickly and easily. But to get the best possible results, you need to choose the right blade for the job.

A blade with 24 teeth is a good choice for general-purpose cutting. If you need to make cleaner, smoother cuts, opt for a blade with 40 or more teeth. However, keep in mind that blades with more teeth require more power from the saw, so be sure to match the blade to the capabilities of your saw.

With the right blade in place, you can tackle any woodcutting project with confidence.

What Are the Different Types of Cuts You Can Make with A Circular Saw?

When it comes to making precise cuts, a circular saw is one of the most versatile tools you can have in your arsenal. Whether you’re trimming lumber for a construction project or cutting through sheet metal for a repair job, this powerful tool can handle the task. But what are the different types of cuts you can make with a circular saw?

The most common type of cut is the straight cut. As the name suggests, this is simply a clean, straight line that’s perpendicular to the edge of the material you’re cutting. To make a straight cut, simply align the blade of the saw with the mark you want to cut, and then proceed to cut along that line.

Another popular type of cut is the rip cut. Unlike a straight cut, a rip cut runs parallel to the edge of the material. This type of cut is often used when you need to quickly remove a large section of material, such as when trimming boards down to size. To make a rip cut, simply adjust the blade of your saw so that it’s at a 90-degree angle to the edge of the board, and then proceed to make your cut.

Finally, there’s the crosscut. As its name implies, a crosscut runs at a 90-degree angle to the material’s edge and grain. This type of cut is often used for cutting lumber into smaller pieces, such as when making dowels or other small components. To make a crosscut, simply align your saw’s blade with the mark you want to cut, and then proceed to make your cut.

With these three types of cuts, you can tackle just about any wood-cutting job. So whether you’re building a deck or repairing a fence, make sure you’ve got a trusty circular saw by your side. Keep reading for more information about how to make circular saw marks on wood.

How Do You Roughen Wood?

Roughening wood is a technique used to create a rough surface on the wood for better adhesion of paint, stain, or other finishes. There are several ways to roughen wood, with the simplest method being to use sandpaper. The coarseness of the sandpaper used will determine the degree of roughness achieved. The recommended grits for rough sanding should be between 40 and 60.

Another way to roughen wood is by using a wire brush or a scrubbing pad. Wire brushes are effective in removing any dirt or debris that might hinder the adherence of finishes. However, applying the brush carefully is essential to avoid damaging the wood’s surfaces.

If you’re looking to achieve a more uneven or rustic texture on the wood’s surface, you can use a saw blade or a chisel. Simply run the saw blade along the surface of the wood, making shallow cuts or notches. For the chisel method, hold a sharpened chisel against the surface of the wood at an angle and gently tap it with a hammer to create small, shallow grooves.

How Do You Stain Rough Saw Lumber?

Staining rough-sawn lumber may seem challenging, but it can be done easily if you follow a few simple steps. First, ensure that the lumber is clean and dry before beginning. Depending on the condition of your lumber, you must sand or scrape it to remove any surface roughness. Once it is thoroughly cleaned and prepped, you can apply a wood conditioner to the surface of the wood.

This will help the stain to absorb evenly across the surface. Next, select a stain for your lumber, and use a brush or a spray gun to apply it. You must ensure that the stain is applied evenly to the surface of the wood, and you must wipe off any excess stain to prevent uneven pigmentation. Finally, allow the stain to dry entirely before applying a sealant to the surface of the wood to protect your finished product.

How is Rough Sawn Lumber Made?

Rough-sawn lumber is made by cutting logs into boards using a sawmill. The logs are stripped of their bark and cut into rough slabs with a circular saw. These slabs are then run through a thickness planer to remove any roughness and make them uniform. The resulting boards are referred to as “rough sawn” because they still have the saw marks from the cutting process.

It can also be made from a variety of wood species, including cedar, pine, oak, and maple. The size and thickness of the boards can also vary depending on the needs of the customer. This type of lumber is commonly used for a variety of projects, including furniture making, cabinetry, and construction. Rough-sawn lumber is also known for its durability and strength, making it a versatile material for a wide range of applications.

What Type of Wood Is Best for Making Circular Saw Marks?

Certain woods are better than others for making precise, clean cuts with a circular saw. Softer woods, like pine, are easy to cut but tend to chip and splinter more readily. Harder woods, like oak, are more difficult to cut but produce cleaner, smoother cuts. As a general rule of thumb, the harder the wood, the better it is for making precise cuts with a circular saw.

However, this is not always the case, as some hardwoods can be very difficult to cut correctly. For example, cherry wood is quite hard but also highly susceptible to chipping and splintering. Ultimately, the best way to determine which type of wood is best for your project is to experiment with different types and see what produces the best results.

Conclusion

So there you have it – how to make circular saw marks on wood. It’s not difficult, but you must take your time and use the right techniques so that your cuts are straight and even. We hope you found this guide helpful, and please don’t hesitate to leave a comment if you have any questions. Happy woodworking!