Do you have a wooden object that appears bent and not in its original shape? If so, you may be dealing with cupped wood. Cupping occurs when one side of the board swells and curves due to exposure to moisture. This condition can ruin the look of your piece if left untreated, making it appear warped or uneven. Fortunately, there are ways to fix this issue and restore your wooden item back to its former glory – it just takes some elbow grease and the right materials!

In this blog post, we’ll cover exactly what cupped wood is and how to fix cupped wood using four simple steps. Whether you have a piece of furniture, a floorboard, or any other wooden item with cupping issues, follow these steps to get it back in shape.

Read on for more information about this common issue so you can get started fixing yours today!

What Will You Need?

Before you begin the process of how to fix cupped wood, it’s important that you have the right materials on hand. Gather the following items, and you’ll be ready to go:

- A heavy weight (such as a sandbag, kettlebell, or other heavy objects).

- A clean cloth

- A vacuum cleaner

- Wood glue

- Sandpaper (either course or fine grain)

- An air compressor (optional)

Once you have all the necessary materials collected, you can begin fixing your cupped wood.

10 Easy Steps on How to Fix Cupped Wood

Now that you have these items ready to go let’s move on to fix cupped wood!

Step 1: Clean the Affected Area

The first step of fixing cupped wood is to prepare the area for work by cleaning it with a damp cloth and vacuum cleaner. This will help remove all dirt, dust, and debris before you apply any adhesive materials or start sanding. You can also use an air compressor to blow off any remaining particles.

Step 2: Glue the Board Together

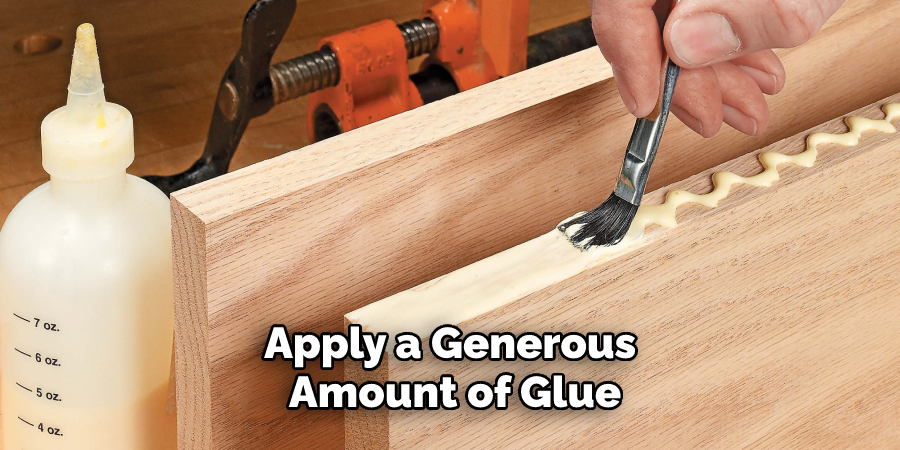

Once the area is clean and free of dust and debris, it’s time to apply wood glue. Line up the edges of the board so that they are perfectly flush. Apply a generous amount of glue between both sides and clamp them together with clamps or weights (such as sandbags).

Step 3: Let it Dry

Let your glued board dry for at least 24 hours before moving on to the next step. If needed, you can use a fan or air compressor to speed up this process. This will ensure that the glue has been set properly and is ready to be sanded.

Step 4: Sand Down any Rough Edges

Once the glued boards are completely dry, you can begin sanding down any rough edges using coarse or fine-grain sandpaper. Take care not to damage the surrounding areas of your piece when sanding. You can use an air compressor to blow away any sanding dust or debris if needed.

Step 5: Re-glue the Boards Together

Once the edges have been smoothed down, you can re-glue the boards together and clamp them again with weights or clamps. Let this bond dry for another 24 hours before proceeding to the next step. Don’t forget to clean up any excess glue on the surface with a damp cloth.

Step 6: Sand Away Any Excess Glue

Once the glued boards are dry, use a course or fine-grain sandpaper to lightly sand away any excess glue that may remain on your surface. Be sure not to damage any of the surrounding areas when doing this as it will ruin your piece’s appearance once complete. Use the air compressor again to blow away any sanding dust if needed.

Step 7: Vacuum Away Any Dust

Now that you’ve sanded down any excess glue, it’s time to vacuum away any dust or debris that may remain on your piece. Use a vacuum cleaner with a soft brush attachment to ensure you get in all the nooks and crannies. Try to avoid using an air compressor, as it can blow away particles that are too small for the vacuum cleaner to pick up.

Step 8: Reapply Wood Glue

After you have finished vacuuming the area, apply a generous amount of wood glue along the edge of the board and clamp them together (if needed). Let this bond cool for 24 hours before proceeding to the next step. Be careful not to apply too much glue, which can lead to a sloppy finish.

Step 9: Sand Away Any Excess Glue Again

Once the glued boards are dry, you can use coarse or fine-grain sandpaper to lightly sand away any remaining glue on your surface. Take care not to damage the surrounding areas. Because you’ve already vacuumed the area, there should be less debris and dust to worry about.

Step 10: Vacuum Away Dust Once More

The final step in fixing cupped wood is to vacuum away any remaining dust or debris. This will help ensure your piece is as clean and smooth as possible before applying a finish. Remember, use a vacuum cleaner with a soft brush attachment to avoid damaging the wood.

By following these ten steps, you are now well on your way to fixing your cupped wood. With a little bit of patience and dedication, you’ll have your piece looking as good as new!

5 Additional Tips and Tricks

1. If the cupped wood is located on a tabletop surface, you can use a hand planer to flatten it. Slowly move the planer in an even pass across the entire board and check your progress as you go.

2. Use a belt sander to smooth out any remaining bumps or uneven spots in the cupped wood after using a hand planer. Make sure to keep the belt running at a low speed and adjust pressure accordingly so that you don’t damage the wood further.

3. If there are minor depressions in the cupping, fill them with glue before sanding or planing them down. This will help to make sure that they stay filled while you work on leveling out all of the other areas.

4. If the cupping is more severe, you may need to use a router to even out the surface. Work slowly and steadily and make sure that your passes are even across the entire board so that it remains level.

5. If all else fails, cut off any severely cupped pieces of wood and replace them with new ones. Make sure to sand down the edges of the new boards until they fit perfectly into place. This method can be time consuming but will ensure that your project looks professional when it’s finished.

Follow these tips and tricks for fixing cupped wood, and you’ll be on your way to completing your project in no time! Remember that patience is key in this process – take your time and don’t rush the job, or you may end up doing more harm than good.

5 Things You Should Avoid

1. Don’t use a hammer or other blunt object to flatten cupped wood. Doing so could damage the grain of the wood and cause further splitting or cracking.

2. Avoid placing heavy objects on top of cupped wood, which will exacerbate the issue and worsen it.

3. Do not apply too much pressure when attempting to repair cupped wood – using too much force can lead to further splintering and breakage, ultimately ruining your project.

4. Don’t soak cupped wood in water or any other liquid for extended periods of time; doing so may cause the boards to swell up even more than before.

5. Try not to sand unevenly when addressing possible cup issues in your workpiece. Doing so may result in an overall unbalanced look that can be difficult to reverse.

The best approach for fixing cupped wood is to use a combination of gentle yet firm pressure, proper sanding techniques, and the right kind of glue or adhesive. Be sure to take your time and do it right the first time — you don’t want to have to start all over again!

Conclusion

By taking the time to do your research, choosing the right fixative, and having patience with the process, you can easily repair the cupped wood in your home. Whether it’s a coffee table, an antique hutch, or some other wooden furniture piece- fixing it yourself is satisfying and could save you lots of money.

Plus, knowing how to fix cupped wood can help you prevent issues from occurring in the first place! Make sure that your wooden items don’t sit in direct sunlight and high-humidity areas to ensure they remain sturdy and beautiful over time.

Taking these preventive measures and following proper steps for repair when needed will keep your furniture pieces looking great years later. So take some time today to gain a basic understanding of wood cupping so you can get the most out of your investments for many years to come.

Hopefully, the article has been helpful in arming you with the knowledge needed to tackle any related issue! Good luck, and happy fixing!