If you’ve ever dreamed of creating a one-of-a-kind, glossy artwork piece, deep-pouring epoxy might be the perfect creative solution. With its stunning clear finish and easy application process, your epoxy project could become a showpiece for any home interior.

Whether you’re new to epoxying or just need some tips before starting your own project, this blog post will help guide you through the entire process of how to deep pour epoxy from start to finish.

We’ll cover everything from preparation and pouring techniques to curing and finishing so you can create unique art pieces with professional results. Read on to find out more about how deep-pour epoxy works and why it’s becoming increasingly popular in DIY art projects!

What is Deep Pour Epoxy?

Deep-pour epoxy is a type of resin that has a longer curing time compared to traditional epoxy. This allows for thicker pours, making it ideal for projects such as river tables, countertops, and other large-scale art pieces. The thickness of the pour creates a stunning 3D effect with depth and clarity that cannot be achieved with regular epoxy.

In addition to its aesthetic appeal, deep-pour epoxy is also highly durable and resistant to heat, scratches, and UV light. This makes it a great choice for functional pieces such as coasters or cutting boards that are both beautiful and practical.

Tools and Materials You Will Need to Deep Pour Epoxy

- Epoxy resin and hardener

- Mixing cups or containers

- Stir sticks

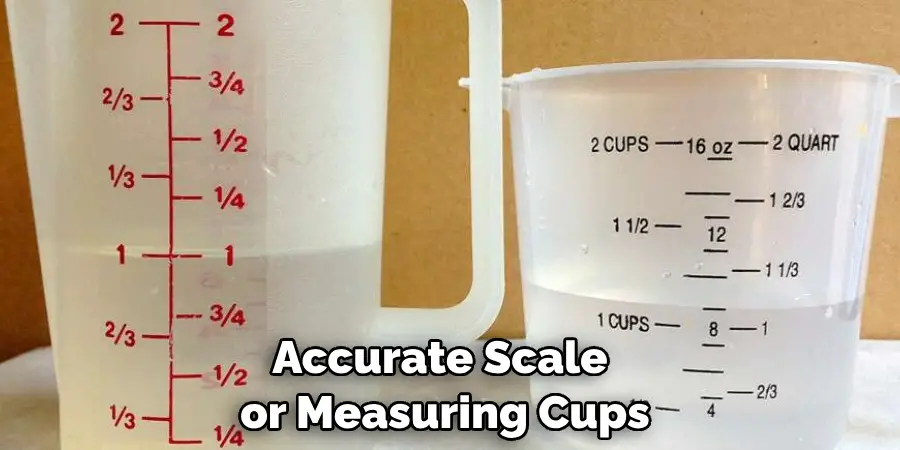

- Measuring tools (scale, measuring cups)

- Heat gun or torch to remove air bubbles

- Silicone molds (if desired)

- Safety gear (gloves, mask, protective eyewear)

Step-by-step Guidelines on How to Deep Pour Epoxy

Step 1: Prepare Your Workspace

Before starting your epoxy project, it’s important to prepare a clean and level workspace. This will ensure that your pour is even and free of debris. Cover your work surface with a plastic drop cloth or wax paper to protect it from any potential spills. Preparing your workspace also means ensuring proper ventilation and wearing protective gear to avoid any potential health hazards.

Step 2: Measure and Mix Your Epoxy

Follow the manufacturer’s instructions for the correct ratio of resin to hardener. Using an accurate scale or measuring cups, combine the two components in a mixing container. Make sure to mix thoroughly until the mixture is fully blended and free of any streaks. Measuring and mixing accurately is crucial for a successful pour.

Step 3: Remove Air Bubbles

After mixing your epoxy, it’s important to remove any air bubbles that may have formed during the mixing process. This can be done with a heat gun or torch by quickly passing over the surface of the epoxy. You can also gently blow on the surface or use a toothpick to pop any visible bubbles. Removing air bubbles will ensure a smooth and clear finished product.

Step 4: Pour Your Epoxy

Slowly pour your mixed epoxy onto your prepared surface. To achieve the best results, it’s recommended to pour in thin layers of 1/8 inch at a time, allowing each layer to fully cure before adding another. This will prevent excessive heat buildup and potential cracking. You can also add color pigments or other decorative elements in between layers for a unique design.

Step 5: Curing and Finishing

After your final layer has been poured, allow your epoxy to cure according to the manufacturer’s instructions. This typically takes 24-72 hours depending on the brand and temperature of your workspace. Once fully cured, you can sand and polish the surface for a smooth, glossy finish. Your deep-pour epoxy art piece is now ready to display and enjoy!

Following these step-by-step guidelines will help you successfully create stunning deep-pour epoxy projects. With its versatility and durability, the possibilities for unique and beautiful creations are endless. So why not give it a try and see where your creativity takes you? Happy epoxying! So go ahead, grab your materials and tools, and start creating your own masterpiece with deep-pour epoxy today!

Additional Tips and Tricks to Deep Pour Epoxy

- Use a pressure pot or vacuum chamber to remove any bubbles in the epoxy before pouring it.

- To achieve a clear and smooth finish, use a heat gun or torch to remove any remaining bubbles on the surface of the cured epoxy.

- Make sure to level your project before pouring the epoxy. This will ensure an even pour and prevent any pooling or uneven thickness.

- Avoid pouring epoxy in temperatures below 60°F as it may result in a cloudy or hazy finish.

- If you are pouring onto a porous surface, such as wood, it is recommended to seal the surface with a sealant or multiple coats of epoxy before pouring to prevent air bubbles from escaping and causing imperfections.

- To add depth and dimension to your project, consider adding layers of different colors or materials in between epoxy pours.

- Practice safety precautions when working with epoxy, such as wearing protective gear and working in a well-ventilated area.

- If you are creating a large project, consider pouring the epoxy in sections instead of all at once. This will allow for easier handling and ensure an even cure.

- Don’t be afraid to experiment with different techniques and additives, such as glitter or pigment powders, to create unique and personalized projects.

- Always read the instructions on your epoxy product carefully and follow them for best results. Every brand may have slightly different mixing ratios and curing times.

- Allow your project to cure fully before handling or using it. This can take anywhere from 24 hours to several days depending on the thickness of your pour and the type of epoxy used.

Following these tips and tricks will help you achieve professional-looking results with your deep-pour epoxy projects. Remember to have fun and get creative with this versatile medium! So, keep practicing and exploring different techniques to create stunning epoxy projects that will impress everyone. Happy crafting!

Precautions Need to Follow for Deep Pur Epoxy

- Before starting the deep pour epoxy process, always make sure to wear proper protective gear such as gloves, safety glasses, and a respirator mask. Deep-pour epoxy can be harmful if it comes in contact with your skin or eyes.

- It is important to work in a well-ventilated area when using deep-pour epoxy. The fumes from the epoxy resin and hardener can be strong and may cause irritation or dizziness.

- When mixing the epoxy resin and hardener, make sure to follow the manufacturer’s instructions carefully. Using incorrect ratios of resin to hardener can result in an incomplete cure or a weak finished product.

- To ensure a smooth and even pour, it is recommended to use a leveling tool such as a spreader or squeegee. This will help eliminate any air bubbles and create a level surface for the epoxy to cure.

- While pouring the epoxy, it is important to monitor the temperature of the room and the mixture itself. Extreme temperatures can affect curing time and may also cause issues with the finished product.

- Deep pour epoxy should be handled with caution when working with large volumes. It is best to have a partner assist with pouring and spreading the epoxy to avoid any accidents.

- After the deep-pour epoxy has been poured, it is important to periodically check for any air bubbles that may rise to the surface. These can be removed using a heat gun or by gently blowing on them with a straw.

- Once the epoxy has cured, it is recommended to lightly sand the surface to remove any imperfections or brush marks. This will create a smooth and polished finish.

Following these precautions will help ensure a successful deep-pour epoxy project and minimize any potential risks or issues. Remember to always handle the materials with care and follow proper safety protocols to protect yourself and others. Happy crafting!

Advantages of Using Deep-pour Epoxy

- Deep-pour epoxy is a durable, versatile, and long-lasting material.

- It has excellent adhesion properties, making it ideal for use on various surfaces such as wood, concrete, and metal.

- Deep-pour epoxy is resistant to water, chemicals, and abrasions.

- It can create a smooth and glossy finish that enhances the look of any surface.

- Compared to traditional epoxy, deep-pour epoxy has a longer working time, which allows for more intricate designs and larger projects to be completed.

- It is self-leveling, resulting in a professional-looking finish without the need for extensive sanding or polishing.

- Deep-pour epoxy can be tinted with pigments or mixed with other materials such as glitter or mica flakes to create unique and personalized designs.

- It is also UV-resistant, making it suitable for both indoor and outdoor use without fear of yellowing or discoloration over time.

- Deep-pour epoxy can be used for a wide range of applications, including countertops, tabletops, bar tops, and even flooring.

- It is easy to work with and requires minimal equipment, making it accessible to DIY enthusiasts and professionals alike.

These are just some of the many advantages of using deep-pour epoxy for your next project. With its durability, versatility, and aesthetic appeal, it is no wonder that this material has become increasingly popular in recent years.

Conclusion

Now you know how to deep pour epoxy like a pro. You’ve learned about the proper tools and materials needed, as well as the steps involved in the process. Remember to always follow safety precautions when working with epoxy, and never rush or cut corners. With practice, you will be able to create beautiful and durable deep-pour epoxy projects for your home or business.