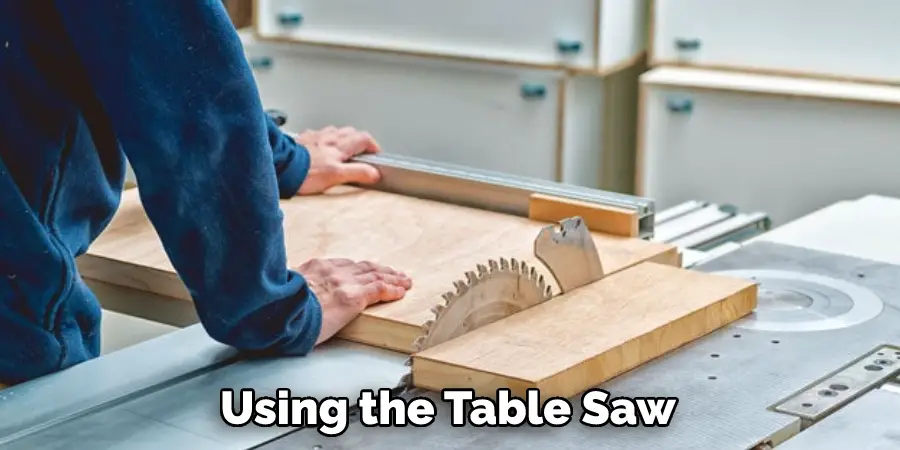

Are you looking for a way to make your table saw more accurate and safe? If so, then you might want to consider building a workstation for it. Building your own workstation is a great way to save money and get the perfect setup for your needs. In this tutorial, we’ll show you how to build a table saw workstation that is both stable and safe. We’ll also provide tips on how to customize it to fit your specific needs. So whether you’re a beginner or an experienced woodworker, follow along with this tutorial and build yourself the perfect table saw workstation!

Is It Cheaper to Buy or Build a Workbench?

It’s always cheaper to build a workbench than it is to buy one. Depending on the type of wood you use, the cost could be as low as $20 or as high as $200 (or more!). But this doesn’t mean that buying a pre-made workbench won’t save you time and effort. If you’re short on time or prefer an easier route, then purchasing a ready-made workbench is definitely an option for you. While not as customizable, it will still get the job done.

10 Methods How to Build a Table Saw Workstation

1. Plans

The first step is to find some plans for your workstation. You can find a variety of plans online or in woodworking magazines. Once you have found some plans, take some time to review them and make sure they are complete and easy to follow. Try to make sure that you will have enough room for all of your tools and supplies.

2. Materials

Next, you will need to gather all of the materials you will need to build your workstation. This includes lumber, hardware, and any other supplies you will need. Make sure you have everything you need before you begin so you do not have to stop in the middle of the project. If you are unsure about what you will need, consult with a professional for help.

3. Cut the Lumber

Once you have all of your materials, the next step is to cut the lumber to size. This can be done with a saw or power tool. If you are using a saw, be sure to use a straightedge to guide your cuts, so they are precise. You will also need to sand the cut edges and make sure all of your pieces fit together properly. However, if you are using a power tool, it is often easier to use a jigsaw and simply follow the lines on your plans.

4. Assemble the Frame

After the lumber is cut, it is time to assemble the frame of the workstation. This is typically done by attaching the boards together with screws or nails. Be sure that the frame is square and level before moving on to the next step. make sure that all of the boards are securely fastened together.

5. Attach the Tabletop

The next step is to attach the tabletop to the frame of the workstation. This can be done with screws or nails. Be sure that the tabletop is level and flush with the frame before moving on to the next step. However, if you are using a power tool, it is often easier to use a circular saw and follow the lines on your plans. If you are unsure, consult with a professional for help.

6. Attach the Fence

The fence is what will guide your cuts when using the table saw, and it needs to be attached next. This can be done with screws or nails as well. Be sure that the fence is level and flush with the tabletop before moving on to the next step. Additionally, make sure that the fence is securely fastened to the tabletop and will not move during use.

7. Attach Other Accessories

Depending on what type of workstation you are building, there may be other accessories that need to be attached at this point, such as drawer slides or dust collection ports. Follow the instructions for your specific workstation plans when attaching these items. Also, be sure to check that everything is level and flush before moving on to the next step. Try to make sure that all of the accessories are securely fastened to the frame and tabletop.

8. Finish It Up!

Once all of the accessories are attached, it is time to finish up your workstation! This includes sanding down any rough edges, staining or painting if desired, and adding any final touches such as handles or knobs. Be sure to follow the instructions provided in your plans when completing this step. However, if you are unsure, consult with a professional for help.

9. Testing It Out!

Before you can call it a finished project, you need to test out your workstation. Set up the table saw on the tabletop and make sure that everything is working properly and as expected. If there are any issues or discrepancies, now is the time to fix them before you start using your new workstation for projects.

10. Enjoy Your New Workstation!

Once everything is tested and working properly, it’s finally time to enjoy your new workstation! Start using it for all of your woodworking projects, and enjoy having a dedicated space for all of your tools and supplies. Congratulations on building your own workstation!

By following this guide and using the right materials, you can easily build your own workstation from scratch. With a bit of planning and some hard work, you can have a functional and beautiful workstation to use for all of your woodworking projects.

Things to Consider When Building a Table Saw Workstation

1. Safety:

Before you start any project involving a table saw, make sure to read the manual and understand all safety precautions needed for the safe operation of the tool. Always wear protective equipment such as goggles, ear protection, and dust masks when using a table saw. Ensure that your workspace is well-lit and free from clutter.

2. Space Requirements:

Consider how much space you have available to devote to your workstation before purchasing a table saw or building materials. Make sure to measure both the width and length of the area where you plan on constructing your workstation before buying any supplies. In addition, make sure to leave enough room around the table saw so that it can be safely operated without running into walls or furniture nearby.

3. Comfort:

Make sure to carefully plan out your workspace so that you can comfortably use the table saw for long periods of time. Include features such as adjustable tables and chairs, padded armrests, and footrests for optimal ergonomics. Also, consider adding an anti-vibration mat underneath the table saw to help reduce fatigue from standing on a hard surface.

4. Structure:

It’s important to build your workstation with durable materials that are designed to last through heavy usage. Opt for materials such as plywood or MDF board when constructing the tables, shelves, and cabinets in your workspace. Use wood glue and screws when assembling them together.

5. Storage:

If you plan on keeping your table saw out in the open, make sure to include plenty of storage so that you can keep all necessary tools and materials organized. Include shelves, cabinets, and drawers to store accessories such as blades, clamps, sandpaper, etc.

6. Electrical Requirements:

Make sure that your workspace has an outlet close by where you can plug in your table saw. If the workstation is larger than the length of a single extension cord or power strip, consider installing an additional electrical outlet for convenience. In addition, use a surge protector to help prevent any power surges from damaging your tool or equipment.

7. Dust Removal:

Sawdust can be hazardous if inhaled over time and can easily accumulate on any surface. Therefore, it’s important to consider ways to minimize sawdust in your workspace. Invest in a dust collector or shop vac, and make sure that any exhaust from the table saw is near an open window or door for proper ventilation.

8. Mobility:

If you plan on moving your workstation around often, consider purchasing wheels or casters to make the process easier. Make sure that the table and all of its components are securely locked before transporting it from one location to another.

9. Accessories:

There are many different accessories available for table saws, such as jigs, attachments, blades, miter gauges, feather boards, clamps, etc. Consider which ones would be beneficial to have when constructing your workstation. Having the right tools will make your job much easier and help increase accuracy while working on projects.

Conclusion

A great workstation starts with the right tools. A table saw is an essential part of any woodworking shop, so it’s important to choose one that fits your needs and budget. With a little planning and some basic carpentry skills, you can build a sturdy, and functional table saw workstation that will make your woodworking projects easier and more enjoyable. Now that you know how to build a table saw workstation, what are you waiting for? Get started on your very own today and see just how much easier your woodworking projects will be.

You Can Check It Out to Build a Wooden Ramp Over Steps