Sanding uneven wood surfaces is important for many projects. It can help create a smooth, level surface that will be easier to paint or stain and provide a professional-looking finish. Sanding can also remove scratches, dents, and other blemishes resulting from everyday wear and tear. With careful sanding, you can ensure that the wood is ready for your project.

Sanding uneven wood surfaces allows you to level out the surface and create a smooth, even finish. Sanding with the wood grain will help prevent splinters and give you a more consistent finish. The amount of sandpaper needed for each job depends on the size of the area you are working on, but typically it is best to start with a medium to coarse grit and work your way up to a finer grit.

Using the correct technique in sanding will also provide better results. In this blog post, You will learn in detail how to sand uneven wood surfaces.

How Do You Identify an Uneven Wood Surface?

There are a few ways to identify an uneven wood surface. The first is to look at the grain of the wood. If the grain is not straight, then the surface is likely uneven. Another way to identify an uneven surface is to look for gaps in the wood. The surface is probably uneven if there are spaces between the boards.

Finally, you can try to place a level on the surface. The surface is most likely uneven if the level does not sit evenly. These are just a few ways to identify an uneven wood surface. If unsure, it is always best to consult a professional before attempting any repairs.

Step-by-Step Processes for How to Sand Uneven Wood Surfaces

Step 1: Inspect the Wood Surface

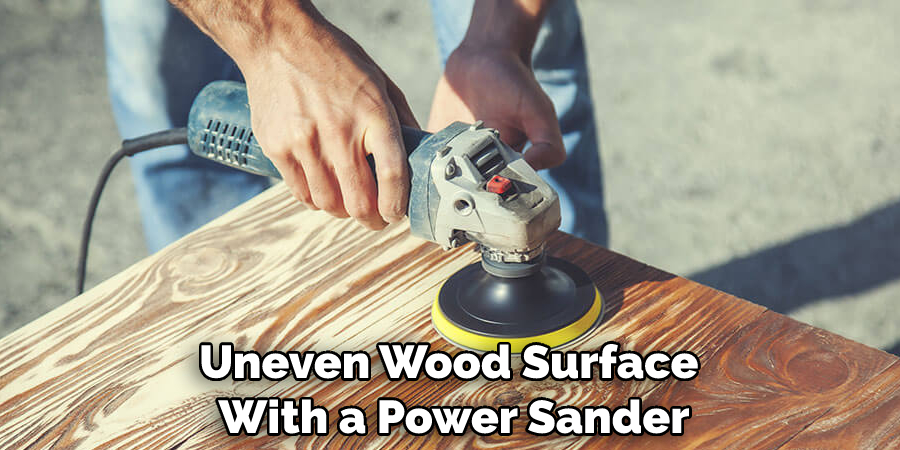

Carefully inspect the wood surface to determine the extent of sanding required. Collect all necessary materials, including a power sander, sandpaper, vacuum cleaner, and safety equipment such as a dust mask and protective glasses.

Step 2: Start Sanding

Start sanding the uneven wood surface with a power sander, using the appropriate sandpaper grit for the job. Begin at one end of the surface and work in even strokes from side to side, following the grain of the wood. Make sure to keep a vacuum cleaner handy for collecting dust during sanding.

Step 3: Sand in the Opposite Direction

Once the surface has been sanded with the power sander, switch to hand-sanding and use a finer grit of sandpaper. Again, start at one end of the wood surface and work in strokes from side to side. However, this time sand in the opposite direction of the grain.

Step 4: Reduce Sanding Pressure

To reduce the pressure on the wood surface and prevent gouging, sand in short strokes from side to side. Move your hand over the surface while applying minimal pressure. This will help eliminate any deep scratches or marks that may have been created after using the power sander.

Step 5: Test the Sanding Progress

After hand sanding, inspect the surface to check if it is smooth and even. If there are still scratches or marks present, switch back to the power sander and use finer grit sandpaper to get rid of them. Keep testing until the wood surface is even.

Step 6: Remove Dust and Residue

Remove all the dust and residue from the wood surface using a vacuum cleaner. As an additional precaution, use a damp cloth to remove any remaining dust particles that may be lodged in crevices or uneven areas on the wood surface. Once the wood surface is even, it is time to apply a primer or stain. This will help protect the wood and give it an attractive finish. Make sure to follow the directions on the can of primer or stain for best results.

Step 7: Apply a Clear Finish Coat

Once the primer or stain has been applied, it is time to apply a clear finish coat. This will seal the wood and provide additional protection from damage. Again, make sure to follow the instructions on the can for the best results. Once the clear finish coat has been applied, buff the surface with a clean cloth. Use a lint-free cloth to remove any dust or residue that may have been missed during previous steps.

Step 8: Inspect the Finished Surface

Once all the steps have been completed, inspect the wood surface to ensure it is even and smooth. If it is satisfactory, you can proudly enjoy the results of your hard work.

How Do You Avoid Creating a Dip in the Surface While Sanding?

When working with wood, it is important to avoid creating a dip in the surface while sanding. The easiest way to do this is to use a sander that has been specifically designed for curves. Another option is to use a hand sander, which can be more difficult to control.

For best results, start with a coarse grit sandpaper and work your way up to a finer grit. Sand in the direction of the grain and take care not to over-sand any one area. With a little practice, you can create a smooth, even surface free of dips and other imperfections.

How Should You Maintain Your Wood Surfaces After Sanding Them?

How you maintain your wood surfaces after sanding them depends on the chemicals you use during the sanding process. If you use any type of skin contact-type product, such as rubber gloves, a respirator, or a face mask, you should take these off immediately after finishing and wash your hands and exposed skin. You should also give any exposed clothing a good wash.

If you were working with bare wood or sanded off any paint or other finishes, you should wipe down the area with a tack cloth to remove any dust before continuing. If you’re going to stain or finish the wood, now is the time to do it. Once that’s done, you can apply a new layer of paint or varnish or put on new hardware. Finally, if you’re just cleaning up existing paint or finishes, you can use a vacuum to suck up any residual dust before giving the area a final wipe-down with a clean cloth.

Instructions for How to Sand Uneven Wood Surfaces

- Start with coarse sandpaper, such as 60-grit, to remove most of the material quickly and efficiently. If the wood surface is particularly rough, you may need to start even coarser to get an even finish.

- Once you have removed most of the unevenness in the wood, move on to 100-grit sandpaper. This will provide a finer finish while removing any remaining bumps and dips on the surface.

- Continue to move up in grit, using finer sandpaper until you reach at least 220 grit. This should give the wood a smooth, even surface that’s perfect for finishing.

- Once you have the desired surface, use a damp cloth to wipe away any dust that’s been created by sanding. This will help ensure an even finish when applying paint or stain.

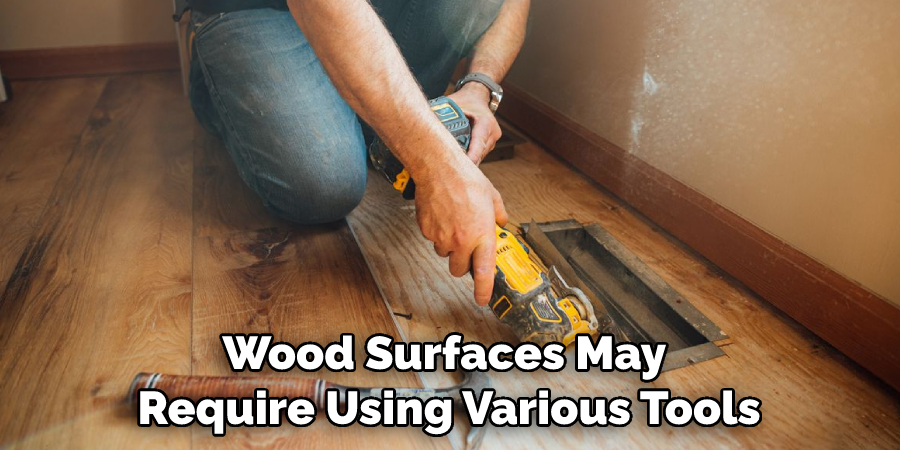

- To ensure all areas of the wood are properly sanded, use an orbital sander in conjunction with your hand sanding. This will help you get into all the nooks and crannies of your surface to make it as smooth as possible.

- When sanding with an orbital sander, use short strokes and do not apply too much pressure, as this can leave marks on the wood. Be sure to keep moving from one side to the other to avoid any unsightly grooves or ridges.

- Finally, use a vacuum cleaner with a brush attachment to remove the majority of the dust created by sanding. This will help prevent clogging and keep your work area clean and safe.

Sanding wood surfaces can be intimidating, but following these steps will make it much easier and result in a beautiful, even finish. Have fun and enjoy your newly finished product.

How Much Will It Cost to Sand Uneven Wood Surfaces?

The cost to sand uneven wood surfaces will vary depending on the size of the project, the type of tools and materials used, and labor costs. Generally, basic hand-sanding costs range from approximately $0.50 to $1 per square foot. Professional services may be more costly for larger projects due to specialized equipment and additional labor. If you are unsure of the cost, it is best to get a quote from a professional contractor who can provide an accurate estimate.

Sanding uneven wood surfaces may require using various tools, such as belt and orbital sanders, scrapers, files, rasps, and/or chisels. For larger projects, specialty tools, such as an oscillating spindle sander or a router with special attachments, may also be needed. Make sure to read the instructions for each tool and use protective gear, such as gloves and goggles, when necessary.

Conclusion

The biggest disadvantage of sanding uneven wood surfaces is the amount of time involved. Depending on the severity of the damage, it can take a significant amount of time to even out all the bumps, ridges, and dips in the wood. Additionally, you must be very careful when sanding – if you apply too much pressure or use an abrasive that is too coarse, you can easily cause further damage to the wood and make the problem worse. If you do not sand all surfaces evenly, it can lead to an uneven finish in staining or painting.

In conclusion, sanding uneven wood surfaces is not as difficult as it may seem. By following the steps outlined above – including evaluating the wood surface, selecting the right tool and materials, preparing the space for sanding, using two-directional strokes to remove scratches, and ensuring a smooth finish – you can successfully achieve your desired results. I hope this article has been beneficial for learning how to sand uneven wood surfaces. Make Sure the precautionary measures are followed chronologically.