If you’re looking for a clean and polished look for your woodworking projects, round the edges of your boards with a Dremel. It’s a quick and easy way to give your project a finished appearance. This tutorial will show you how to round wood edges with a dremel. Read on to learn more!

Summary: The traditional way to round wood edges is to use a hand saw. However, this can be time-consuming and tedious, making it difficult to get consistent results. One solution is to use a Dremel tool. This small, handheld tool can quickly and easily round wood edges using a variety of cutting techniques. You can even use it to create subtle curves ornaments.

What Causes You Round the Edges of Wood?

There are a few reasons you might want to round the edges of the wood. Maybe you’re looking for a way to create softer, more organic lines in your project. Maybe you’re trying to avoid sharp edges that could splinter or cause injury. Or maybe you want your project to look more polished and professional. Regardless of your motivations, rounding wood edges with a Dremel is a great way to achieve your desired look.

Another reason to round wood edges might be to create a more comfortable grip for someone who will be using the piece. For example, if you’re making a custom wooden walking stick, you might want to round the edges so that it’s more comfortable to grip. Lastly, rounding the edges of wood can also help to prevent splintering. It’s not foolproof, but it’s a good way to reduce the risk of your project splintering along the edges.

Why Should You Round Wood Edges With a Dremel?

A Dremel is a great tool for rounding wood edges because it’s quick, easy, and gives you much control. You can use it to create both large and small radius curves, and you can adjust the depth of your cut to create different effects. Plus, a Dremel is relatively inexpensive, so it’s a great tool to have on hand for various woodworking projects. Another great thing about using a Dremel is that it’s very easy to find replacement parts and accessories. So, if you damage your bit or want to try a different edge style, it’s easy to find what you need.

Additionally, Dremels are relatively compact, so they’re easy to store and transport. Finally, Dremels are very versatile. In addition to rounding wood edges, you can use them for various other tasks, such as sanding, drilling, and carving.

Step by Step How to Round Wood Edges With a Dremel

1. Protecting Your Work Surface

The first step is to protect your work surface. You don’t want your Dremel to damage your countertop or table, so it’s important to put down something that will act as a barrier. You can use a scrap piece of wood, a cutting board, or something similar. Just make sure it’s sturdy and won’t move around while you’re working.

2. Measuring and Marking Your Board

Once your work surface is protected, it’s time to measure and mark your board. First, you’ll need to decide how much of the edge you want to round. For this project, we’re going to round the entire edge of the board. So, we’ll be making a mark 1/4″ from the edge.

But, you can make your mark closer to the edge if you want a more drastic curve. Once you’ve decided how much of the edge you want to round, use a ruler or a tape measure to make a mark at that distance from the edge. Then, use a pencil to draw a line along the entire length of the board at that mark. This will be your guideline.

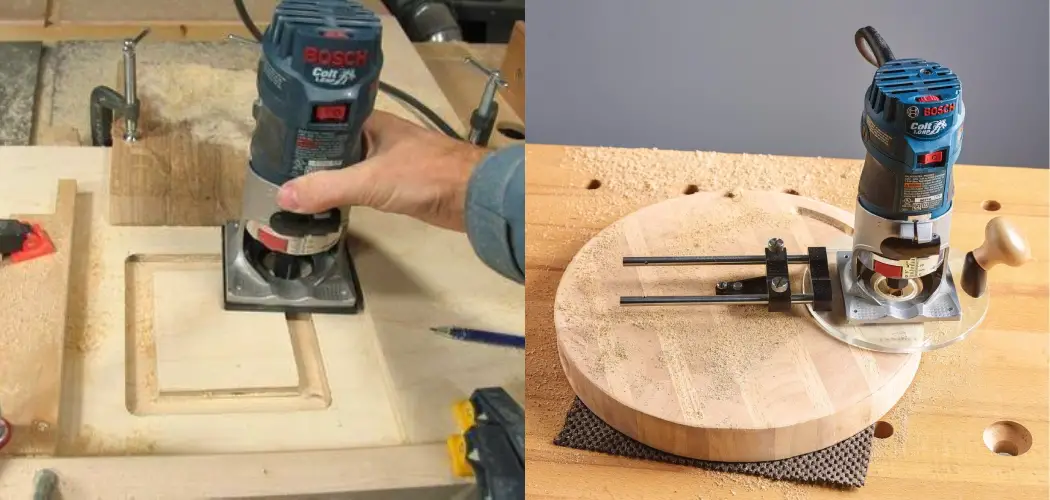

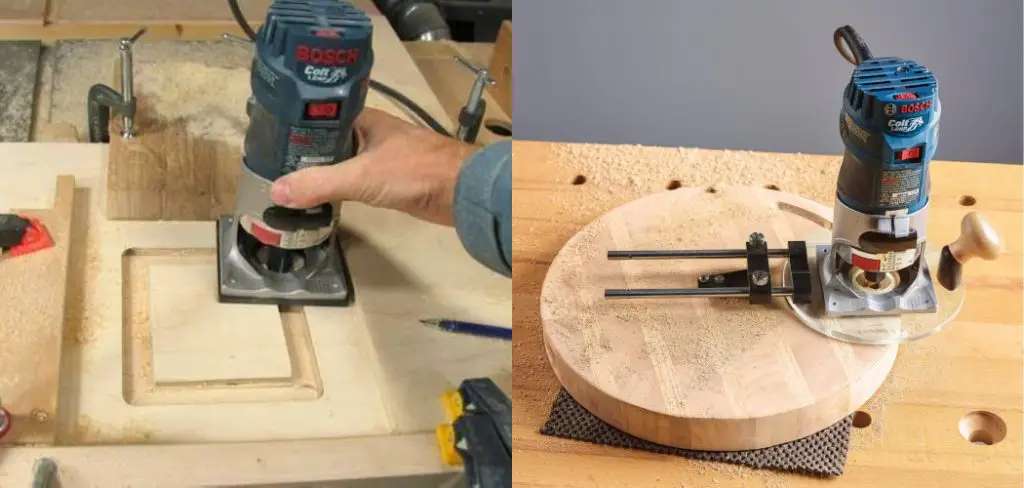

3. Selecting the Right Dremel Bit

Now it’s time to select the right Dremel bit. You can use a few different types of bits for rounding wood edges, but we recommend using a router bit. Router bits come in various sizes, so you can choose one that will create the radius you want. For this project, we’re using a 1/4″ router bit. If you’re not sure which size to use, it’s always better to err on the side of a smaller bit. You can always go back and make the curve larger if you need to.

4. Preparing Your Dremel

Once you have your router bit, it’s time to prepare your Dremel. First, you’ll need to attach the bit to your Dremel. To do this, first, unscrew the collet nut. The small knob at the end of your Dremel holds the bit in place. Once the nut is unscrewed, you can insert your bit into the collet.

Then, screw the collet nut back on to secure the bit in place. If your Dremel has a chuck, you can also use that to hold your bit in place. Just insert the bit into the chuck and tighten it until it’s secure.

5. Adjusting the Depth of Your Cut

Now that your Dremel is prepared, it’s time to adjust the depth of your cut. For this project, we’re going to be making a shallow cut. So, we’ll adjust our cut’s depth to 1/8″. But, you can adjust the depth to whatever you want. Remember that a deeper cut removes more material and creates a more drastic curve. To adjust the depth of your cut, first, unscrew the depth adjustment knob.

Then, slide the router bit up or down to the desired depth. Once it’s at the right depth, screw the knob back on to secure it in place. If your Dremel doesn’t have a depth adjustment knob, you can still adjust the depth of your cut. Just loosen the collet nut and slide the router bit up or down to the desired depth. Then, tighten the collet nut back on to secure it in place.

6. Making the First Cut

Now it’s time to make your first cut. For this project, we’re going to be making a series of small cuts. So, we’ll be using the plunge router technique. This technique is simple and only requires two cuts. First, you’ll need to position your Dremel at the beginning of your line. Then, slowly lower the router bit until it just touches the surface of the wood. You’ll want to ensure that the router bit is touching wood at the edge of the line. If it’s not, your curve will be too shallow.

7. Checking Your Progress

As you’re making your cuts, it’s important to check your progress. This will help you make any necessary adjustments to ensure you’re getting the desired results. To check your progress, run your hand along the edge of the board. This will help you feel how much material has been removed and how the curve is shaping up.

8. Moving to a New Position

After you’ve made your first cut, it’s time to move to a new position. For this project, you’ll need to move the Dremel up the wood, keeping the same 45-degree angle. Make sure that you don’t change the angle of the tool as you move it up the wood. This will ensure that you create a nice, even edge. As you move the Dremel, you’ll need to keep the router bit in contact with the surface of the wood. If you lift the router bit off of the wood, you’ll create an uneven curve.

9. Rounding the Corners

After you’ve gone all the way around the board, you’ll need to round the corners. To do this, first, position the Dremel at the corner of the board. Then, slowly lower the router bit until it just touches the surface of the wood. Now, move the router in a small, clockwise circle.

As you do this, the bit will start to carve out a small groove. Continue moving the router in a circle until you’ve carved out a small indentation. Next, move the router to the next corner and repeat the process. After you’ve rounded all of the corners, your board should have nice, smooth edges.

10. Finishing Up

Once you’re happy with the results. First, remove the router bit from your Dremel. Then, unscrew the guide from the base of the tool. Now is a good time to sand down the wood edges with some fine-grit sandpaper. You can also use a wood sealer or varnish to protect the wood and give it a nice finish.

You Can Check It Out To Remove Wood Appliques

Tips and Warnings on How to Round Wood Edges With a Dremel

Tips:

- Be sure to use a plunge router bit for this project. This type of bit is designed for making small, shallow cuts.

- Make sure the router bit is sharp before you start your project.

- Take your time and go slowly. Rushing through the project will likely result in an uneven curve.

- Use a light touch when operating the Dremel. Pressing too hard will remove too much material and create a more drastic curve.

Warnings:

- Always wear safety goggles when using power tools.

- Be aware of the direction of the router bit. The bit will rotate in the same direction as the arrow on the body of the tool.

- Keep your fingers away from the spinning bit at all times. Use gloves or another form of protection if necessary.

- Do not use a Dremel on wet or green wood. The moisture will cause the wood to warp and splinter.

- Do not try to round sharp corners with a Dremel. This will likely damage the tool and create an uneven curve.

You Can Check It Out To Polish Plastic with a Dremel

Does Walnut Wood Lighten In The Sun?

Walnut wood is known for its rich, dark color and beautiful grain patterns. However, over time and with exposure to sunlight, the color of walnut wood can lighten. This is a natural process that occurs as a result of the sun’s ultraviolet rays breaking down the pigments in the wood. The rate at which the color lightens can vary depending on the intensity and duration of the sunlight exposure.

While some may appreciate the natural color change in walnut wood, others may prefer to maintain the original dark color. To prevent or slow down the process of color lightening, it is recommended to keep walnut wood out of direct sunlight or to use protective coatings or finishes. It is important to note that even with precautions, some level of color lightening is inevitable as the wood ages and is exposed to normal environmental elements.

Is Walnut Wood Naturally Dark?

While walnut wood naturally has a warm and rich look to it, the darkness of the wood depends on various factors, such as the tree’s age, growing conditions, and the part of the tree where the wood is harvested. Walnut trees can take up to 100 years to mature, and the wood will undergo various changes during this time. As the tree ages, the heartwood of the tree becomes darker, giving walnut wood its distinct color.

Additionally, the cut of the wood can also influence its color. Quarter-sawn walnut wood tends to have a more consistent appearance and a straight grain, whereas plain-sawn walnut wood may display some knots, figuring, and variation in color. The finishing process can also impact the final color of the wood, as stains and oils can be used to enhance or darken the natural color of the wood.

Does Wood Get Lighter As It Ages?

Wood is a natural and organic material that can be found in a lot of different products and structures. Over time, wood can experience many changes, whether due to environmental factors, aging, or other external sources. One question often arises is whether wood gets lighter as it ages. The answer to this question is not a simple one, as it depends on a number of different factors.

Firstly, it’s important to understand that wood is much denser when it is young and freshly cut. As it ages, the wood may lose some of its density due to factors such as water loss and natural degradation. This can make the wood appear lighter in weight, although the actual physical weight may not change significantly.

Furthermore, the color of the wood may change over time as well, which can contribute to the perception of it getting lighter. Exposure to sunlight, air, and other environmental factors can cause the wood to lighten or darken over time.

Conclusion

So there you have it! A simple guide on how to round wood edges with a Dremel. With this handy tool, you can easily create smooth, curved edges on any piece of wood. Just remember to take your time, use a light touch, and be careful of the direction of the router bit. Thanks for reading!