Table tops can be created from various materials, but one of the most popular and durable options is wood. If you’re looking to create a wooden tabletop, there are a few things you need to know before you get started. This tutorial will show you how to join wood planks for table top using a few simple tools and techniques. So whether you’re making a new table or repairing an old one, follow these steps to create a sturdy and attractive tabletop.

Summary: If you want to join wood planks for a tabletop, there are a few steps that you need to take. First, cut the wood into even-sized pieces. Next, use a wood glue and wood screws to attach the wood planks together. Finally, stain or paint the tabletop to match your home’s decor.

Things You Will Need

- Tape measure

- Pencil

- Circular saw, or hand saw

- Chisel

- Hammer

- Nail set

- Pry bar

- Carpenter’s glue

- Construction adhesive (optional)

- 1 1/2″ finishing nails

- High-grit sandpaper

How to Join Wood Planks for Table Top Step by Step Guide

1. Measuring the Length and Width

The first step is to measure the length and width of your tabletop. You’ll need to know the dimensions of your table to cut the planks to size. Once you have the measurements, use a pencil to mark the dimensions on each plank. If you’re using multiple boards, be sure to label them so you can keep track of where each one goes.

2. Cutting Wood Planks to Size

Once you have your boards cut to size, it’s time to start joining them together. If you’re using a circular saw, ensure the blade is set to cut through the wood barely. This will help prevent the boards from splintering as you work.

If you’re using a hand saw, you may need to make more than one pass to cut through the wood. Just be careful not to splinter the boards as you work.

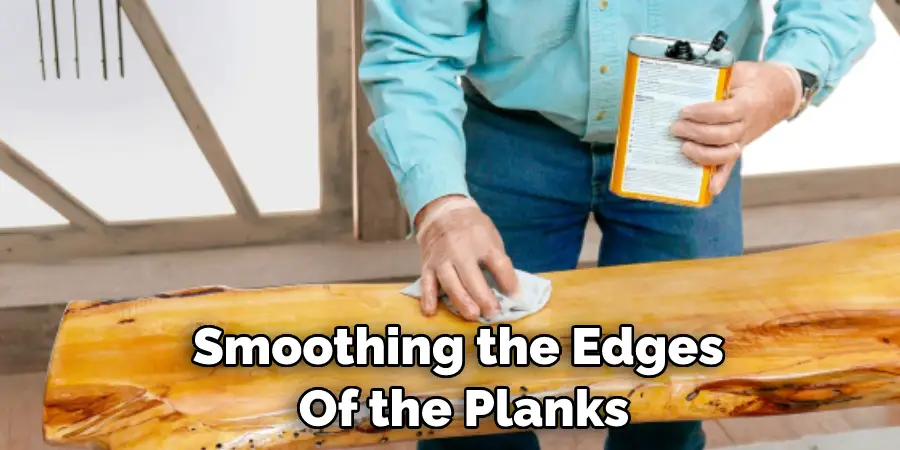

3. Smoothing the Edges of the Planks

Once all of the boards are cut to size, it’s time to smooth the edges. You can use a chisel and hammer to remove any rough spots or splinters. If you’re working with multiple boards, be sure to chisel the edges of each one, so they fit together snugly.

4. Joining the Wood Planks Together

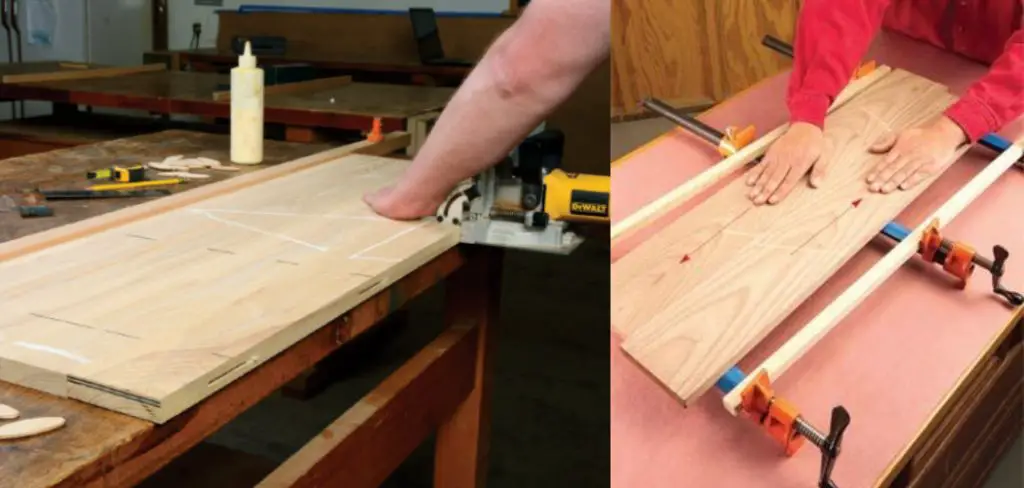

Now it’s time to start joining the boards together. If you’re using carpenter’s glue, apply a thin layer to the edges of each board. Then, fit the boards together and clamp them in place. Let the glue dry for at least 30 minutes before moving on to the next step.

If you’re using construction adhesive, apply a generous amount to the edges of each board. Then, fit the boards together and press them firmly in place. The adhesive should set in about 30 minutes.

5. Securing the Wood Planks Together

Once the glue or adhesive is set, it’s time to secure the boards. If you’re using nails, drive two 1 1/2″ finishing nails into each joint. Be sure to sink the nails below the surface of the wood so they can be covered with putty later.

If you’re using screws, drive two screws into each joint. Be sure to countersink the screws so they can be covered with putty later.

6. Clamping the Joints Together (optional)

If you’re having trouble getting the boards to stay in place, you can try clamping them together. Just be careful not to clamp them too tightly, or you may damage the wood. If you’re using screws, you can also try driving them in from the other side of the joint.

7. Filling the Joints

Once the boards are secured in place, it’s time to fill the joints. If you’re using putty, apply it to the joints and smooth it out with your finger. Be sure to wipe away any excess putty before it dries. If you’re using wood filler, apply it to the joints and smooth it out with your finger. Again, be sure to wipe away any excess filler before it dries.

8. Applying Finish Nails (optional)

If you’re using finish nails, now is the time to drive them into the joints. Be sure to sink the nails below the surface of the wood so they can be covered with putty later. If you’re not using finish nails, skip to the next step.

9. Trimming Excess Nail Length (optional)

If you’re using finish nails, you’ll need to trim the excess length off of each one. You can use a nail set and hammer to sink the nails slightly below the surface of the wood, then use a sharp chisel to trim them off flush. If you’re using brad nails, you can use a wire cutter to trim them flush with the surface of the wood.

10. Filling the Nail Holes (optional)

If you’re using finish nails, you’ll need to fill the nail holes before moving on to the next step. You can use wood putty, a product made specifically for this purpose, or sand the area around the nail until it’s flush with the rest of the wood.

11. Sanding the TableTop

Once the joints are filled and the nail holes are filled (if necessary), it’s time to sand the tabletop. If you’re using a hand sander, you’ll want to use 120-grit sandpaper. If you’re using a power sander, you can start with 80-grit sandpaper. Either way, you’ll want to work your way up to finer grit sandpaper (150-grit or higher). Sanding is an important step because it will smooth out the imperfections in the wood and help to prepare the surface for staining or painting.

12. Applying the Stain or Paint

Now it’s time to apply the stain or paint. If you’re working with a clear finish, be sure to apply a top coat to protect the wood. To apply the stain or paint, use a brush or roller and work in the grain direction. Be sure to apply a thin, even coat and allow the stain or paint to dry completely before moving on to the next step.

13. Applying the Polyurethane

After the stain or paint has dried, it’s time to apply a polyurethane top coat. Polyurethane is a clear finish that will protect your table from scratches and stains. It’s also what will give your table its shiny, finished look. To apply the polyurethane, pour some into a paint tray and then use a paintbrush to apply it to the table in long, even strokes.

Work in small sections so that the polyurethane doesn’t have a chance to dry before you’ve had a chance to spread it evenly. Once you’ve applied the first coat of polyurethane, let it dry completely before moving on to the next coat. Two coats should be sufficient, but if you want an extra-durable finish, you can apply a third coat. And that’s it! Once the final coat of polyurethane has dried, your table is ready to use.

14. Attaching the Table Top to the Base

If you’re using a table base already built, you can skip this step. But if you’re starting from scratch, then you’ll need to attach the tabletop to the base. You’ll need to use screws or nails and some adhesive to do this. If you’re screwing or nailing the table top to the base, start by aligning the two pieces to flush with each other.

Then, drill pilot holes through the table top and into the base. Next, insert screws or nails into the pilot holes and screw or nail the two pieces together. If you’re using an adhesive to attach the tabletop to the base, apply a bead of adhesive around the base’s perimeter. Then, place the table top on the base and press down to adhere the two pieces together. Allow the adhesive to cure for the manufacturer’s recommended time before proceeding.

You Can Check It Out to Secure Chicken Wire to Wood

Tips and Warnings on How to Join Wood Planks for Table Top

Tips:

- Make sure the wood planks you select are of the same thickness.

- If the planks are not of the same thickness, use a belt sander to even them out.

- The longer the boards, the straighter they will lay. So, choose longer boards if you’re looking for a perfectly flat surface.

- To avoid warping, choose kiln-dried planks.

- Inspect the boards for knots, cracks, and other imperfections before purchasing them.

Warnings:

1. Don’t use construction adhesive or nails to join the wood planks together. The glue will not hold, and the nails will eventually pop out.

2. Don’t use screws to join the wood planks together. The screws will eventually strip out, leaving the boards loose.

3. Be careful not to over-tighten the clamp when joining the boards together. This can cause the wood to warp.

4. If you’re using a power drill, be sure to use a drill bit that is slightly smaller than the screws. This will prevent the screws from stripping out.

5. Be sure to wear safety glasses when using power tools.

How Do You Hide Wooden Seams?

After joining pieces of wood together to form a table top, it is important to hide any visible seams for a smooth and professional finish. Depending on what look you are trying to achieve, there are a few different methods for hiding wooden seams.

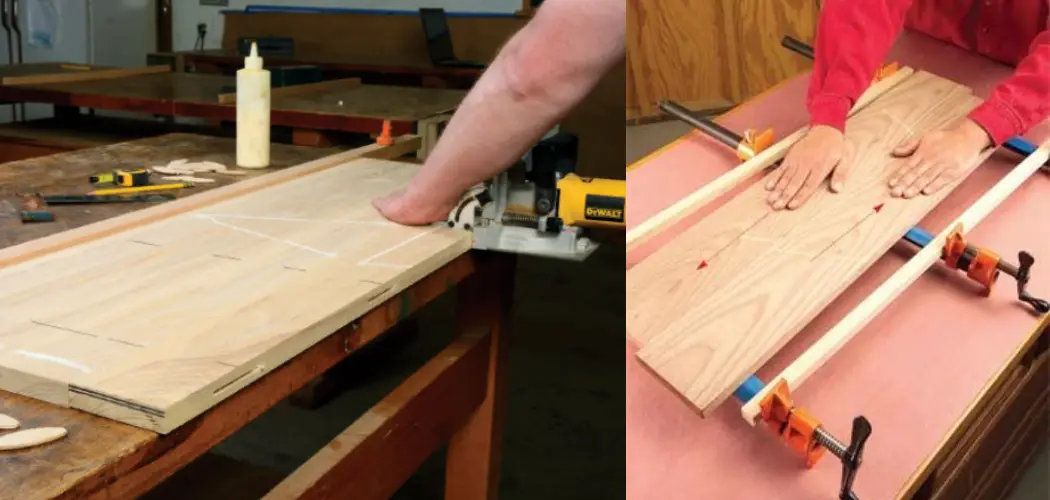

One way of hiding wooden seams is to use a biscuit joiner with biscuits that are the same size as the width of the wood. Start by cutting a shallow groove into each piece of wood along the joint line before inserting biscuits into them. This will ensure that they fit securely and remain hidden in the seam. Secure the pieces together with an adhesive or clamp until dry.

What Kind of Wood Should I Use for a Table Top?

When deciding what type of wood to use for a tabletop, it is important to consider its aesthetics and its durability. Hardwoods such as oak and maple are both popular choices due to their strength and beauty. Oak is a great choice if you want a table top that will last for many years, while maple has an attractive grain pattern that will make your tabletop stand out.

Once you have selected the wood that you would like to use for your tabletop, it is time to learn how to join the planks together. The most common way to do this is with a biscuit joiner. This tool works by cutting a hole in each piece of wood and then inserting a small, oval-shaped piece of wood called a biscuit into the holes. This creates a strong bond between the pieces of wood, allowing them to be joined securely and easily.

How Do You Join Wood Without Nails?

Joining wood planks together to form a tabletop without the use of nails is a fairly straightforward process that can be accomplished in several different ways. The most common method involves using wood glue to create a strong and secure bond between the planks while also providing a seamless look.

To begin, start by selecting two or more pieces of wood that are of similar size, shape, and thickness. It’s important to note that any knots or irregularities must be taken into account when selecting the planks because they can weaken the bond between them.

Conclusion

So, there you have it! Your very own guide on how to join wood planks for table top. By following these simple steps and using the right tools, you can create a beautiful tabletop that will last for years. So, have fun with it, and experiment with different types of wood to find the perfect look for your home. If you have any questions, feel free to leave a comment below, and we’ll be happy to help. Thanks for reading.

You Can Check It Out to Make a Hurdy Gurdy