Tapered table legs can provide a beautiful and unique aesthetic to any piece of furniture, making it stand out from the crowd. With this handy guide, you will learn how to cut tapered table legs with ease! By following these simple steps, you will be able to craft beautiful and unique pieces that are sure to draw attention.

One of the main advantages when it comes to cutting a tapered table leg is that it creates an elegant and professional look. Tapered legs help create a more unified look by making all four legs appear as one, rather than having individual legs with varying heights.

It also helps reduce the amount of space taken up in your room, while still providing adequate support for your furniture. In this blog post, You will learn in detail how to cut a tapered table leg.

Step-by-step Instructions for How to Cut a Tapered Table Leg

Step 1: Inspect the Table Leg

Before beginning, it is important to inspect the table leg for any defects or damage that may affect the outcome of your project. Make sure the wood is free from cracks, knots, and other imperfections.

Step 2: Mark Your Desired Angle

Measure and mark the desired angle onto the table leg with a pencil. The angle can be whatever you prefer – 45 degrees is a popular choice. Measure and mark the desired length of the leg onto the wood and use a saw to cut along the marked lines.

Step 3: Create a Shallow Angle at Each End

Use your pencil markings as a guide for creating shallow angles at each end of the table leg. You can do this with either a saw or chisel. This is where your angled grooves will be cut into one end of the table leg. Use a coping saw, keyhole saw, or even a jigsaw to create your desired pattern.

Step 4: Sand and Refine

Once you’ve made your cuts, use sandpaper to smooth out the edges and refine the surface. Use a rasp to further refine your angled cuts and shape the grooves. Give the leg one final pass with sandpaper to ensure that all of your edges are smooth and even.

Step 5: Finish Your Leg

To give your table leg a professional-looking finish, you can use a wood stain or varnish. Allow the leg to dry completely before using it in your furniture project.

Now that you know the basics of cutting a tapered table leg, you can get started on your next DIY furniture project! With patience and attention to detail, you’ll be able to create beautiful pieces of furniture that will last for years.

Safety Precautions for How to Cut a Tapered Table Leg

- Always wear safety goggles or face shield when cutting the tapered table legs to protect your eyes from any flying wood chips or sawdust.

- Wear ear protection such as ear plugs or noise-canceling headphones while operating power tools to prevent hearing loss.

- Make sure that your work area is clear of any obstructions before beginning to work on your project.

- Make sure the blade of the saw is sharp and has no nicks that may cause kickback or breakage while cutting.

- Securely clamp the wood piece you are cutting in place before attempting to cut it, so that it does not move around when cutting the tapered table leg.

- Avoid placing your hands in the path of the saw blade while cutting as this may lead to injury.

- Make sure that any loose clothing or jewelry is tucked away before operating power tools so that they do not get caught in the blades and cause an accident.

Once you have taken all of these safety precautions, you can start cutting your tapered table legs with confidence and peace of mind. Carefully measure out the desired angle of your leg and follow the instructions on your saw to safely cut the taper.

What is the Best Way to Join Two Pieces of Wood Together at an Angle for a Tapered Table Leg?

When building a tapered table leg, joining two pieces of wood at an angle can be tricky. There are several techniques that can be used to ensure the best fit and strongest joint possible. One of the most common methods for joining two pieces of wood is by using dowels and biscuits.

Dowels are wooden pegs that are inserted into pre-drilled holes in both pieces of wood. The dowels then act as a sort of ‘glue’ and will hold the two pieces together securely. Biscuits are thin, oval-shaped pieces of compressed wood that fit into slots cut into the sides of the two boards being joined.

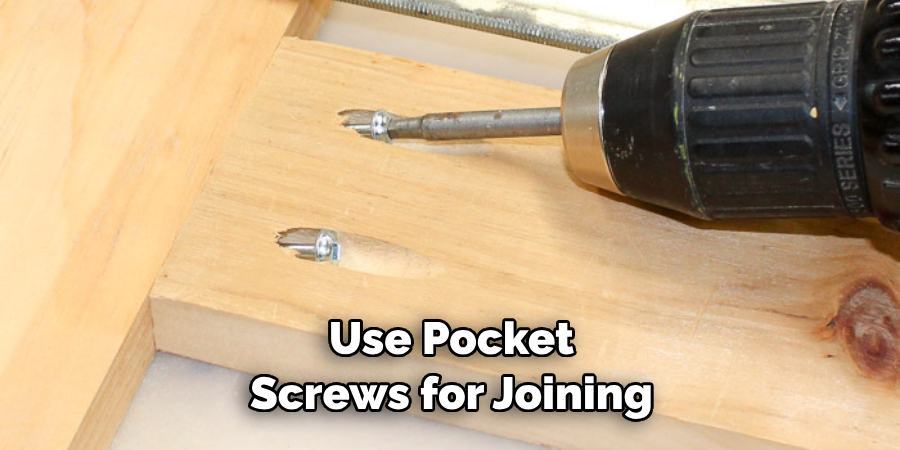

Another option is to use pocket screws for joining your tapered table leg. Pocket screws are specially designed screws that fit into pre-drilled pocket holes in the wood to create a strong joint. Finally, you can use mortise-and-tenon joints for joining your tapered table leg.

This technique involves cutting out a square notch (the “mortise”) in one piece of wood and a corresponding tongue (the “tenon”) in the other piece of wood. The two pieces are then joined by sliding the tenon into the mortise and securing it with glue or screws.

Are There Any Special Techniques That Can Be Used to Ensure a Smooth Line When Cutting a Taper?

Yes, there are some special techniques that can be used to ensure a smooth line when cutting a taper. The most important technique is to use a jig to help guide the saw as it cuts. This will produce an even and precise cut along the entire line of the taper.

It is also important to use sharp blades on the saw in order to achieve a smooth cut. Finally, make sure that the saw is set to the right speed and depth in order to get the best results. By using these techniques, you will be able to create beautiful tapered table legs with professional-looking results every time.

What Are the Benefits and Drawbacks of Using a Jig Saw for Cutting Tapered Table Legs?

Using a jigsaw to cut tapered table legs can be a good choice as it is fast and easy. It also allows for accurate cuts that will provide professional results. The speed with which the cuts can be made makes it an ideal choice for larger projects that require multiple tapers.

The main drawbacks of using a jigsaw for cutting tapered table legs is that the finished product can be somewhat rough and uneven. It also requires a steady hand to ensure accurate results, which may not always be possible for those with less experience.

In addition, this type of saw requires more maintenance than other cutting tools and can be noisy when in use. For best results, it is important to practice on scrap wood before attempting to cut tapered table legs with a jigsaw.

This will help to get a feel for the cutting motion and ensure that you are using the right technique to achieve a smooth line when cutting. Choosing the correct blade is also important – use one designed specifically for making straight cuts, as this will reduce the risk of chipping or splintering.

What Are Some Common Mistakes That Might Occur When Cutting a Tapered Table Leg, and How Can They Be Prevented?

One of the most common mistakes when cutting a tapered table leg is not using the right type of saw for the job. It is important to use a handsaw or circular saw that has sufficient power and blade length to make clean, precise cuts.

Additionally, be sure to use a straightedge guide along with your saw in order to ensure an even cut. If your saw blade is not lined up properly, it can cause the table leg to be uneven and the cut may not be as precise.

Another mistake that might occur when cutting a tapered table leg is using too much pressure while cutting. This can cause the saw blade to bend or break, resulting in an uneven cut. Additionally, it is important to make sure that the saw blade is sharp and in good condition, as a dull blade can cause rough cuts.

Finally, be sure to measure your table leg accurately before cutting. This will help ensure that you make the right type of cut for your project, avoiding wasted material and time.

Conclusion

In conclusion, creating a tapered table leg is straightforward and can be done with some simple tools. You should always remember to wear the appropriate safety gear while using any power tool. Measure twice, cut once! Start by using your saw to make multiple passes at multiple angles in the wood until you have achieved the desired taper angle.

Then use a chisel and hand plane for finer details. Finally, sand the leg to finish. With a bit of patience and practice, you can create beautiful tapered legs for your furniture projects. I hope this article has been beneficial for learning how to cut a tapered table leg. Make Sure the precautionary measures are followed chronologically.