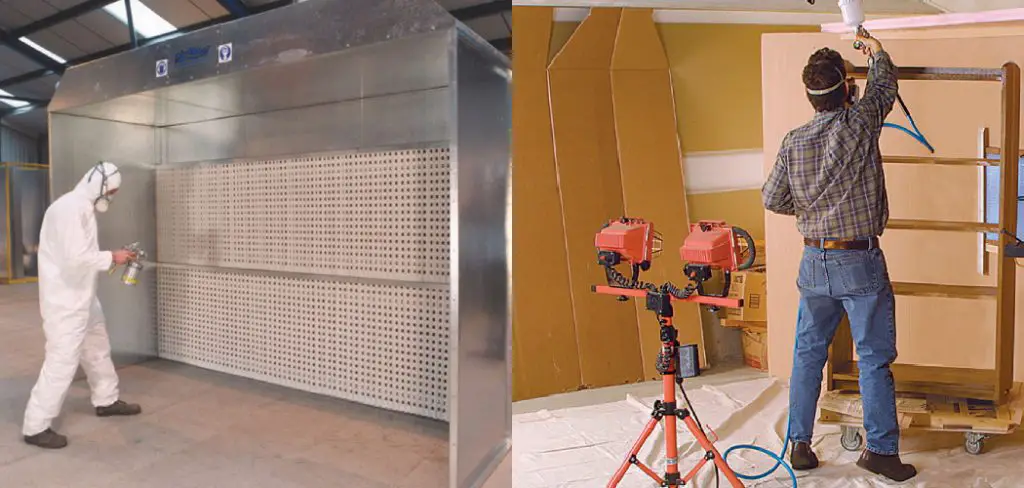

Are you a woodworker who wants to start spraying finishes? If so, you’ll need a spray booth. Having your own spray booth is essential when it comes to spraying finishes. Not only will it protect your surroundings from overspray, but it will also ensure that the finish goes on smoothly and evenly.

In this blog post, we’ll show you how to build a spray booth for furniture using materials readily available at home improvement stores. We’ll also provide tips on setting up and using your spray booth. Read on for more information.

Summary: If you’re looking to spruce up your furniture with a new look, consider building a spray booth for your home. This easy project can be done in just a few hours and will give your furniture a fresh new look. All you need are some supplies, including a spray booth, a garden hose, and some paint or a sealant.

What Tool & Materials You’ll Need

You’ll need the following materials to build your spray booth for furniture:

- 4 wood boards (we used 1″x4″x8′)

- 1 sheet of plywood (we used 5/8″ plywood)

- Construction adhesive

- Caulk

- High-strength magnets

- Spray paint

- Sandpaper

Step by Step Guide: How to Build a Spray Booth for Furniture

Step 1: Cut the Four Wood Boards.

First, cut the four wood boards down to size. You’ll need two boards that are 8 feet long and two 4 feet long. Next, cut the 2×4’s down to size as well. You’ll need four pieces that are 2 feet long and four pieces that are 1 foot long. If you’re using MDF, you will need to cut it down to size. You’ll need one piece that is 4 feet by 8 feet and two pieces that are 2 feet by 4 feet.

Step 2: Assemble the Frame of the Spray Booth.

Next, you will need to assemble the frame of the spray booth. To do this, take the 8-foot long boards and the 2x4s and attach them using wood screws. Make sure that the frame is square by measuring the diagonals. Once the frame is assembled, you can attach the MDF using wood screws or nails.

Step 3: Install the Airflow System.

Now that the frame is complete, you can start working on the airflow system. To do this, take the 4″ PVC pipe and cut it into four sections. Two sections will be for the intake vents, and the other two will be for the exhaust vents.

If the PVC pipe is too long, you can always cut it down to size. Next, take the two intake sections and drill four holes into each section. These holes should be evenly spaced apart and large enough to fit the 4″ diameter hose. Once all the holes are drilled, attach the intake sections to the frame using screws or nails.

Step 4: Attach the Intake Sections.

Now you can attach the intake sections. To do this, take the 4″ diameter hose and insert it into the holes you drilled earlier. Make sure that the hose is snug so that there is no air leakage. Once the hose is in place, you can use the clamps to secure it.

Next, take the 6″ diameter intake section and attach it to the other end of the 4″ diameter hose. Again, ensure that there is a snug fit so that there is no air leakage. Finally, the 8″ diameter intake section is attached to the other end of the 6″ diameter hose. Again, make sure to use hose clamps to secure all connections.

Step 5: Attach the Exhaust Section.

Once the frame is complete, it’s time to attach the exhaust section. This part of the booth will need to be vented to the outside, so ensure you have a good seal around the edges. Next, attach the exhaust section to the frame with screws or bolts, ensuring it is secure. Make sure the intake and exhaust fans are installed and operational before continuing.

Step 6: Install the Lighting.

The next step is to install the lighting. You’ll need two fluorescent light fixtures for this part of the project. These can be attached to the frame using screws or nails. Once the fixtures are in place, you can insert the bulbs and turn them on. If you think the light is too bright, you can always add a diffuser to the fixtures.

Step 7: Hang the Curtain.

The next step is to hang the curtain. This will help contain the paint fumes and keep them from spreading throughout your workspace. To hang the curtain, attach it to the frame with screws or nails. Make sure the curtain is taut so it doesn’t sag in the middle.

Step 8: Connect the Ventilation Duct.

Once you have your frame and walls built, it’s time to start on the ventilation. The essential part of any spray booth is the ventilation system. Without proper ventilation, fumes and overspray can quickly build up and cause health problems.

To ventilate your spray booth, you will need a fan, an exhaust duct, and a fresh air intake duct. When choosing a fan, get one that is powerful enough to move the air through your ductwork. The last thing you want is your booth to be full of fumes because the fan can’t move the air fast enough.

Step 9: Test the Booth.

Once you have everything installed, it’s time to test the booth. Ensure the fans are turned on, and the air moves through the ductwork. You should also check for any air leaks around the edges of the curtain. If everything is working properly, you’re ready to start spraying!

A spray booth is a great option if you’re looking for a way to protect your furniture from paint fumes. By following these simple steps, you can build your spray booth that will keep your furniture looking its best.

Some Helpful Tips and Suggestions

- Decide on the size of your booth. The size will depend on the largest item of furniture you intend to spray.

- Make sure that you have adequate ventilation. This is important for both your safety and the quality of your work.

- Choose a location for your booth that is away from flammable materials.

- Construct your booth using sturdy materials that can be easily cleaned.

- Install filters in your ventilation system to remove any harmful fumes from the air.

- Make sure that your booth is well-lit so that you can see your work.

- Keep your booth clean and tidy to ensure a high-quality finish on your furniture.

- Use a dust cover or tarp to protect your work area from overspray.

Does a Spray Booth Need Ventilation?

A spray booth needs ventilation to remove fumes and overspray from the air. Without proper ventilation, these fumes can build up and cause health problems. To ventilate a spray booth, you need a fan, an exhaust duct, and a fresh air intake duct. The fans should be powerful enough to move the air through the booth at a rate of 1 CFM per square foot of booth area.

The first step in ventilating a spray booth is to install the fans. The fans should be mounted on the booth’s ceiling so that they can pull air up and out of the booth. Make sure that the fans are pointing in the right direction so that they will blow air out of the booth and not into it. If the fans are mounted on the wall, they will not be able to pull all the fumes out of the booth.

How Much Airflow Does a Spray Booth Need?

A spray booth must have 1 CFM of airflow for every square foot of booth area. This means a 10′ x 10′ booth will need 100 CFM of airflow. The fans should be powerful enough to move this amount of air through the booth. If they are not, the fumes and overspray will build up inside the booth, and it will not be a safe or effective workspace.

The other factor to consider is the paint you will use. Water-based paints have much lower VOCs (volatile organic compounds) than oil-based paints, requiring less ventilation. As a result, if you are using water-based paint, you can get away with half the amount of airflow 50 CFM per square foot of booth area.

What Do You Need to Make a Spray Booth?

To make a spray booth, you will need several materials and tools. The first thing you will need is a suitable location. Choose a location that is well-ventilated and free from any flammable materials. Once you have chosen a location, you will need to construct the walls and ceiling of the booth. Constructing the walls, you can use materials such as plywood, drywall, or metal.

Next, you will need a ventilation system. This is essential to remove any fumes or particles that are generated during the spraying process. You can install a ventilation fan on the wall of the booth or on the ceiling. The fan should be connected to ducting that leads to the outside of the building. To ensure the booth is well-lit, you will need to install lighting fixtures.

Fluorescent lights are a good choice because they are energy-efficient and produce a bright, even light. You should also install a filter system to remove any overspray or particles from the air inside the booth. This can be done using a downdraft table or an exhaust filter. The filter should be cleaned or replaced regularly to maintain its effectiveness.

Do You Need Ventilation for a Spray Booth?

Yes, ventilation is essential for a spray booth. A spray booth is an enclosed area designed to contain and remove the overspray generated from the spraying process. The overspray not only affects the quality of the final product but can also have significant health and safety implications. Ventilation ensures the proper removal of these fumes and particles from the spray booth to maintain a safe and healthy workspace.

The ventilation system should be designed to create a unidirectional airflow, moving from the cleanest area to the dirtiest area, i.e., from the worker towards the exhaust. This ensures that the contaminant generated during the spraying process flows away from the operator and out of the booth.

Ventilation systems for a spray booth come in two types: downdraft and cross draft. A downdraft system pulls the air down and away from the operator, while a cross-draft system moves the air horizontally. The choice of the ventilation system depends on the type of material being sprayed and other factors, such as the size of the booth, budget, and space requirements.

Can You Make Your Own Spray Booth?

Yes, it is possible to create your own spray booth. A spray booth is essential for anyone who wants to paint or coat a surface correctly. An enclosed space keeps the paint and fumes contained while providing proper ventilation. To create your own spray booth, you will need to find a space large enough for your project, preferably in a well-ventilated area.

Once you have located the space, you will need to construct a frame using PVC pipes or wood that will serve as the structure. Next, purchase lightweight plastic sheets or tarps that can be stretched around the frame to make a tent-like structure.

Once the structure is in place, you can add an exhaust fan and filter to ensure proper ventilation. Finally, add some interior lighting for better visibility, and you have your DIY spray booth. Remember to wear personal protective equipment such as goggles and gloves while painting or spraying, even inside the booth.

Conclusion

A spray booth is a great investment for any furniture maker. It can help you save time and money while producing a high-quality product. Not only will it protect your work area and furniture, but it will also give you a more professional appearance. If you are considering building your spray booth, follow the instructions in this article to create a safe and effective space for finishing your furniture projects.

By following the instructions in this blog post on how to build a spray booth for furniture, you can build your own spray booth quickly and easily. Have fun with it, and let us know how it turns out! Have you ever built a spray booth before? What tips would you add? Share your thoughts in the comments below!